Materials Performance and Design in Welding and Joining Area[Joining and Welding Research Institute]

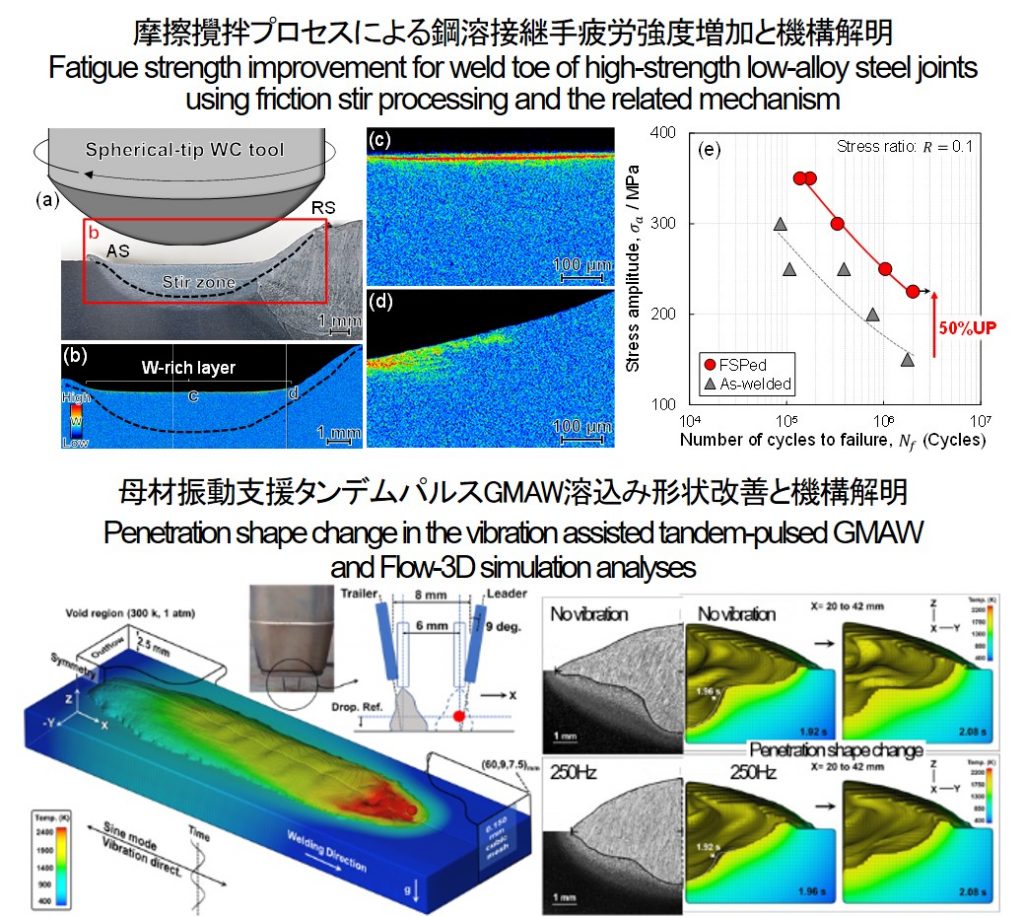

Mechanisms controlling the joint performance of structural and functional materials, which obtained by fusion welding, liquid-state/solid-state bonding, and solid-state bonding, are metallographically characterized to establish a scientific basis to produce joint materials featuring superior performance. The microstructures of the weld-deposited metal, the heat-affected zone of fusion-welded joints, and the interfacial region of solid-state bounded joint are thoroughly investigated utilizing various methods such as X-ray diffraction, electron-microscopy observation, elementary analysis, EBSP analysis, and numerical modeling and simulation. Formation processes of the microstructures and their relation to joint performance are discussed from the material scientific viewpoint.

Top