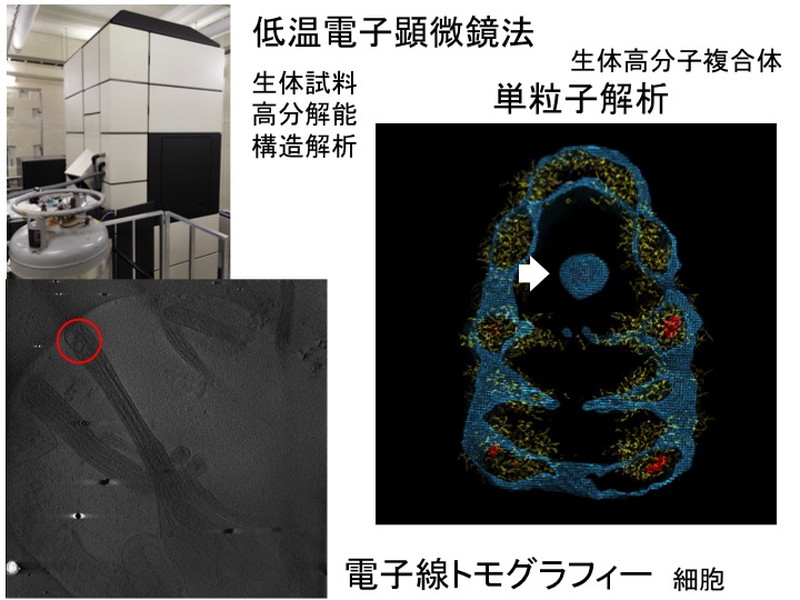

We use electron microscopes to determine the high-resolution structures of bio-molecular complexes. The determined structures can be used to understand the functions of the complexes at molecular and atomic levels for their applications. In addition, we develop the methods for high-resolution structural analysis by ultra-high voltage and cryo-electron microscopy to their wide applications by many researchers.

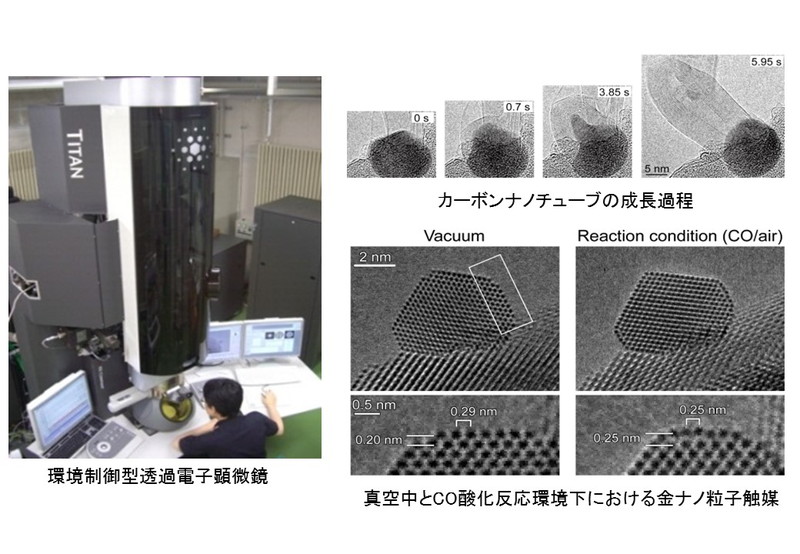

It is crucial to characterize both the fabrication processes and the properties of nanomaterials and devices at real environments. We have been developing electron microscopy techniques for the purposes. High-resolution environmental transmission electron microscopy (ETEM) now allows us to observe various dynamic phenomena in-situ and at atomic scale. With the experimental technique, we aim at creating novel nanostructures and investigating the structures and properties of the nanostructures in real environment for further progress on materials science and technology to the future.

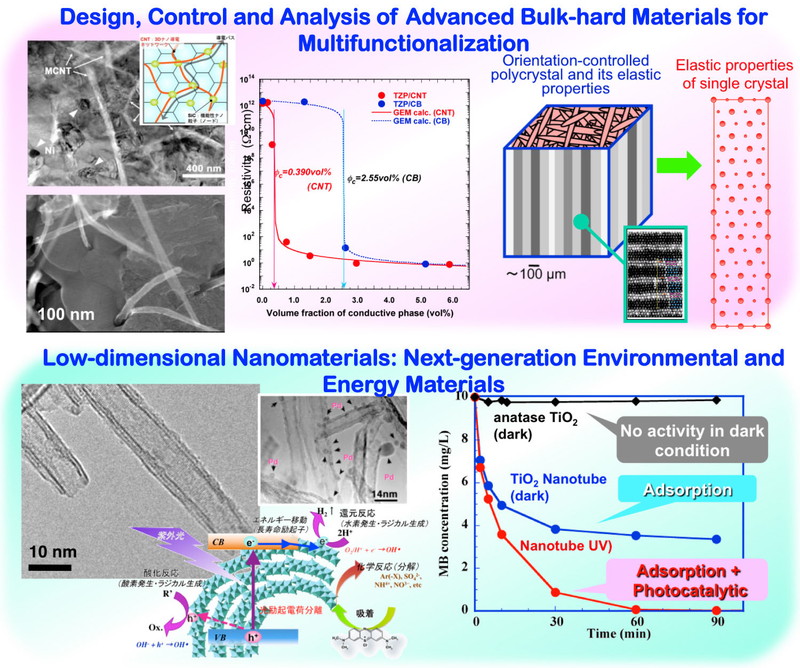

This laboratory is carrying out next-generation materials research and development of ceramics, metals and related materials from crosscutting point of view. The subject covers crystal structures, nano to macro scale hierarchical structural design and process control, fusion of various functions, and fundamental understanding of materials characteristics for advanced hard and nanostructured materials. Our emphasis is placed also on the practical application of developed materials and technologies as the key components for various devices and instruments, next generation biocompatible, environmental and energy systems, all which are the strongly demanded materials technologies to solve crucial problems arising in our society.

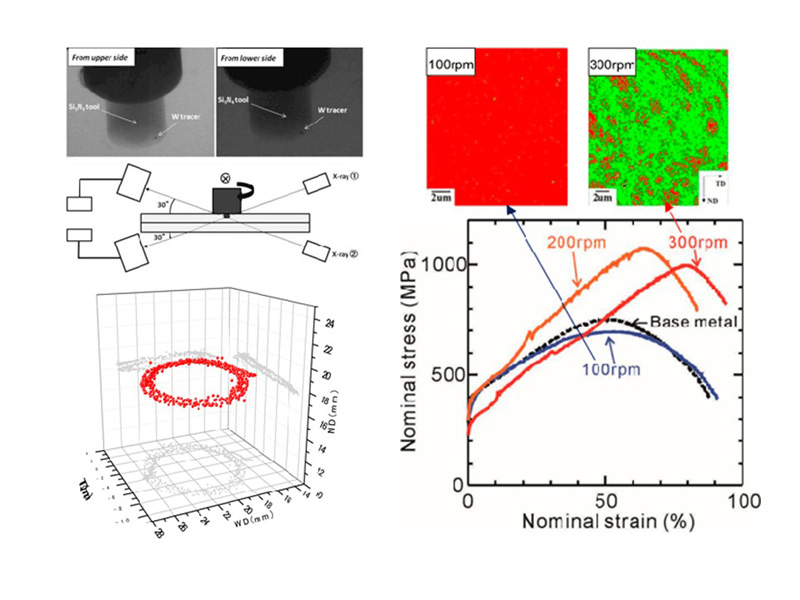

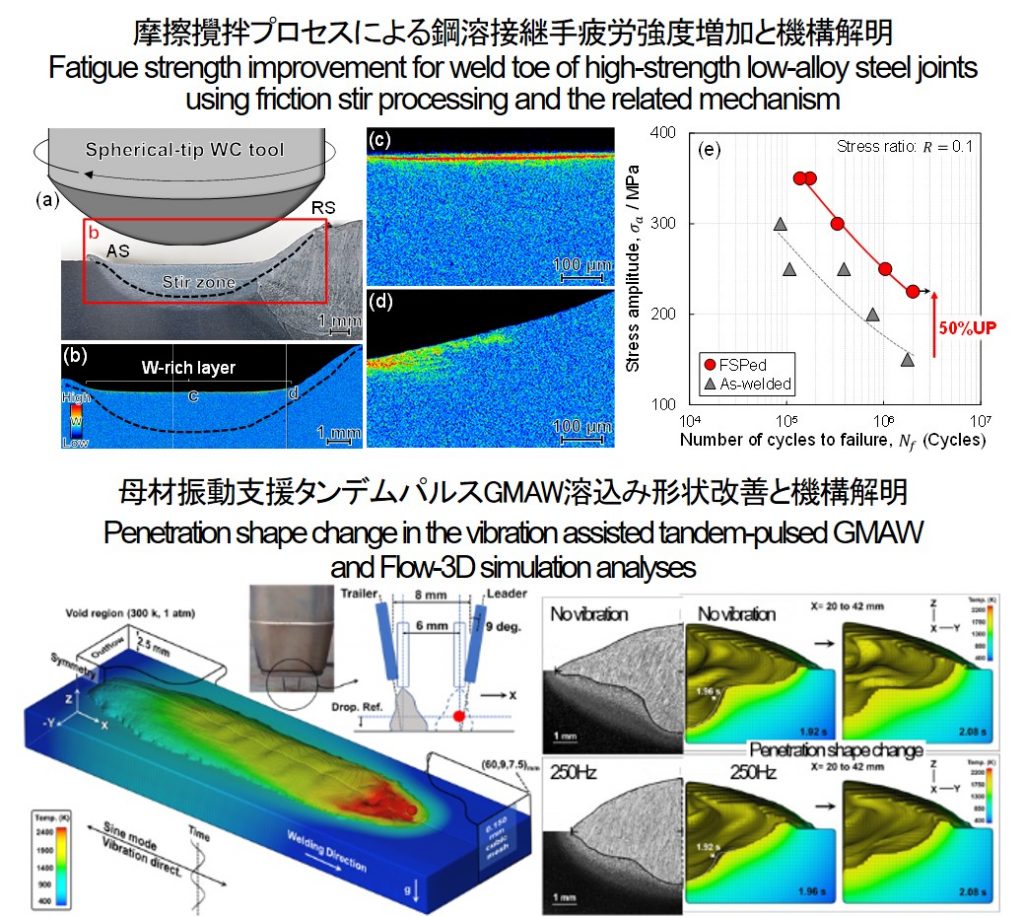

In this department, based on the elucidation of various phenomena at the joint interfaces, the interface formation mechanisms during various welding processes are clarified to create new interface control methods. In addition, novel welding and modification processes are developed, mainly based on fusion welding methods and friction welding methods such as friction stir welding, rotary friction welding, linear friction welding and linear friction stir welding methods. These developments are going to be used and focused simultaneously in our society in order to create a new research field and elevate the growth of industrial competitiveness of our country.

Energy Transfer Dynamics[Joining and Welding Research Institute]

Materials Performance and Design in Welding and Joining Area[Joining and Welding Research Institute]

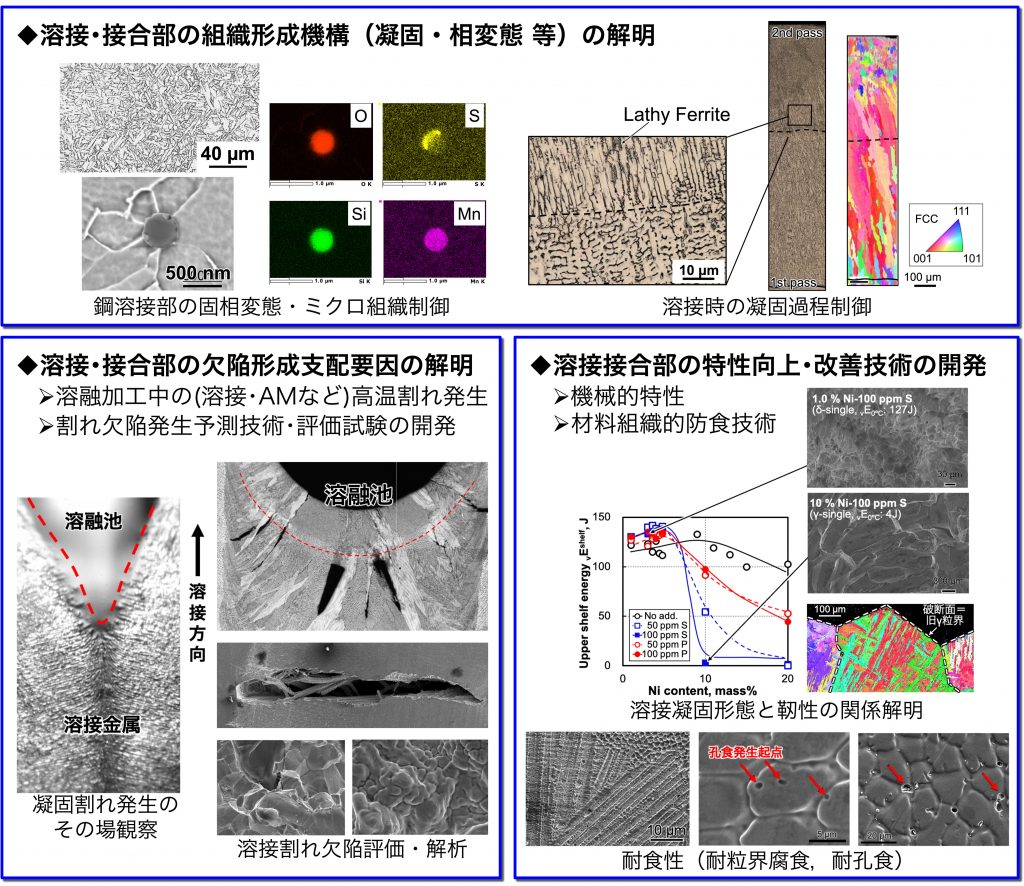

Mechanisms controlling the joint performance of structural and functional materials, which obtained by fusion welding, liquid-state/solid-state bonding, and solid-state bonding, are metallographically characterized to establish a scientific basis to produce joint materials featuring superior performance. The microstructures of the weld-deposited metal, the heat-affected zone of fusion-welded joints, and the interfacial region of solid-state bounded joint are thoroughly investigated utilizing various methods such as X-ray diffraction, electron-microscopy observation, elementary analysis, EBSP analysis, and numerical modeling and simulation. Formation processes of the microstructures and their relation to joint performance are discussed from the material scientific viewpoint.

The main research subject is the development of the high density energy source for processing advanced materials having special functions and properties. We undertake fundamental investigations of the properties of the high energy source interacting with materials, and we study advanced control techniques for optimizing the energy transport. Major emphasis is placed on the generation, control and energy transport in arc plasmas, which are a high density energy source which have been applied to a variety of materials processing techniques such as welding, cutting, heating, high temperature processing, surface modification and the creation of powders.

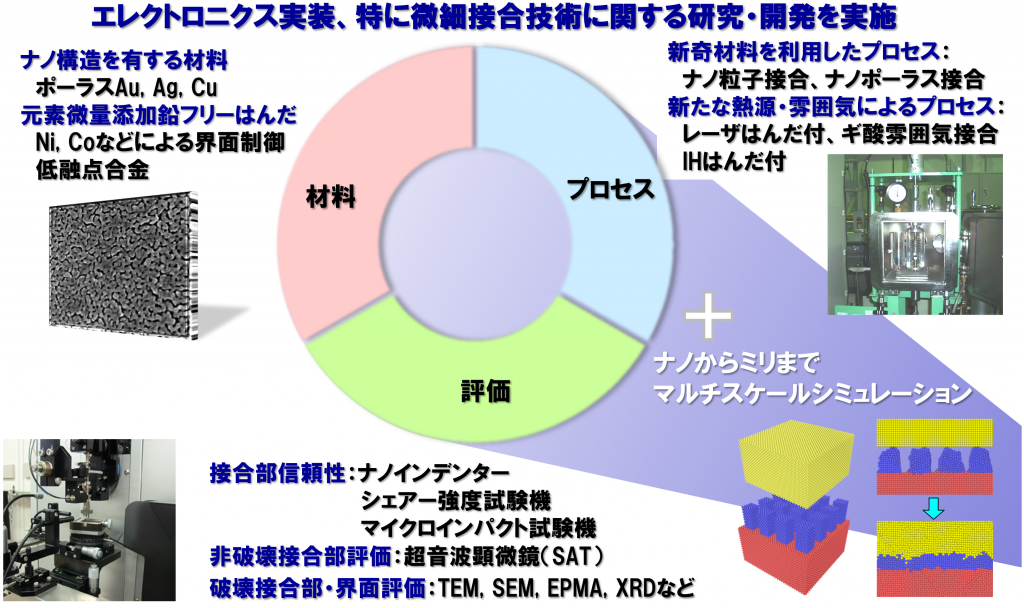

The main research objectives are for electronics packaging to develop advanced joint materials, to establish advanced micro joining processes, and to elucidate the mechanisms of the micro joining processes. Especially, the creation of the functional joint materials, the development of novel advanced micro processes by various energy sources, the understanding of interfacial behaviors in nano-/micro-scale, and the enhancement of the highly reliable joints based on the control of interfacial structure and performance are performed.

Development of innovative manufacturing technology is required to manufacture high-performance machine products and structures of the next-generation. Department of Reliability Evaluation & Simulation conducts research and education for elucidation and control of the factors on weldment properties by high accurate evaluation based on material science and engineering. In order to create innovative and attractive technique of welding & Joining as a final aim, our department are working on elucidation of metallurgical phenomenon such as solidification and transformation, and on developing the predication method for the microstructures and the properties of weldments.

Top