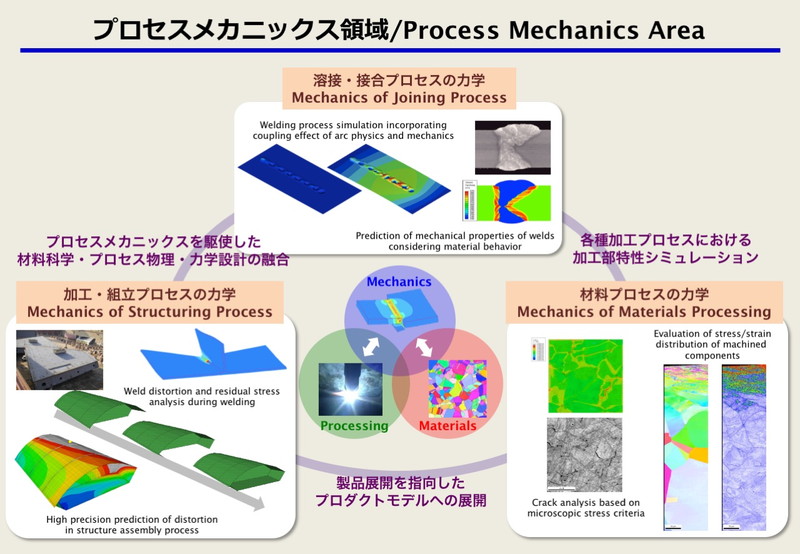

Welding and joining, cutting, machining —essential processing technologies for manufacturing—inevitably generate residual stresses and distortions, and consequently control the performance and integrity of products and structures. “Process Mechanics” is a new discipline to investigate the mechanical behavior related to manufacturing processes on the basis of materials science, physics of processes, and mechanics. Our major approaches are the development of simulation models for manufacturing processes and their application to the prediction of mechanical properties, design, and integrity assessment of components and structures.

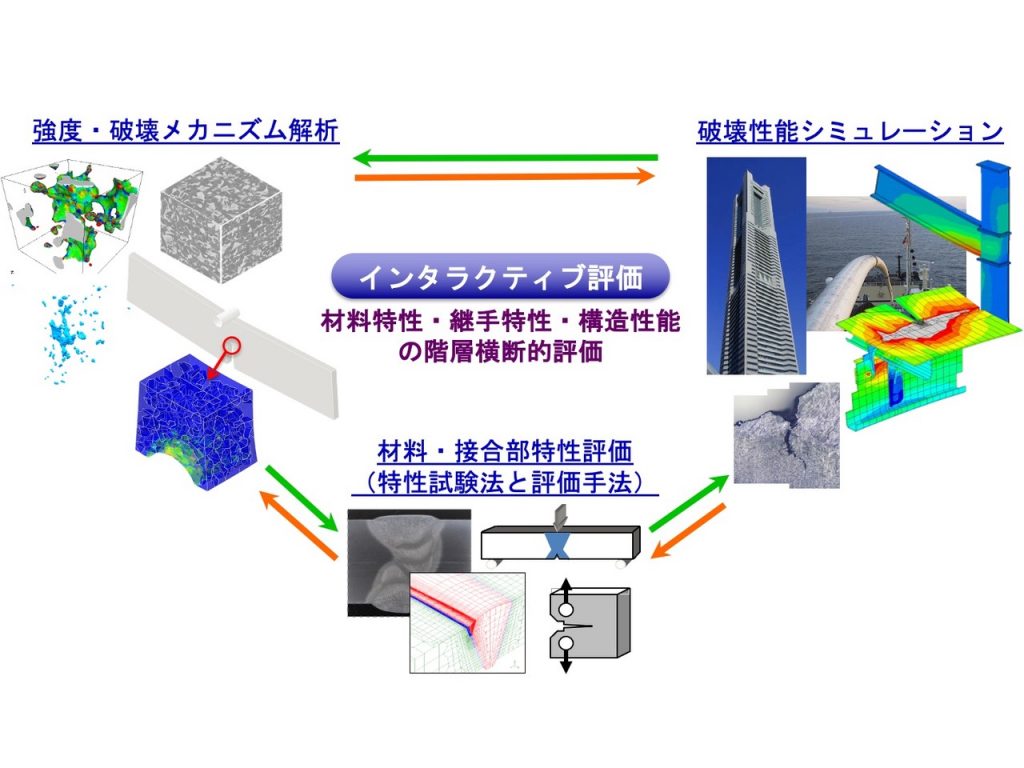

A procedure has been developing for the transferability analysis of the micro-structural properties of materials, strength of welded joints and the fracture performance of structural components, which leads to advanced multi-scale design of infrastructures as well as industrial goods. The study includes the mechanics and mechanism of ductile damage, brittle fracture and fatigue of structural steels. A computational damage simulation with modeling damage and fracture is on going, which enables the link between the materials properties and the structural integrity in terms of the resistance to unstable fracture, crack growth resistance, ductile instability and fatigue fracture.

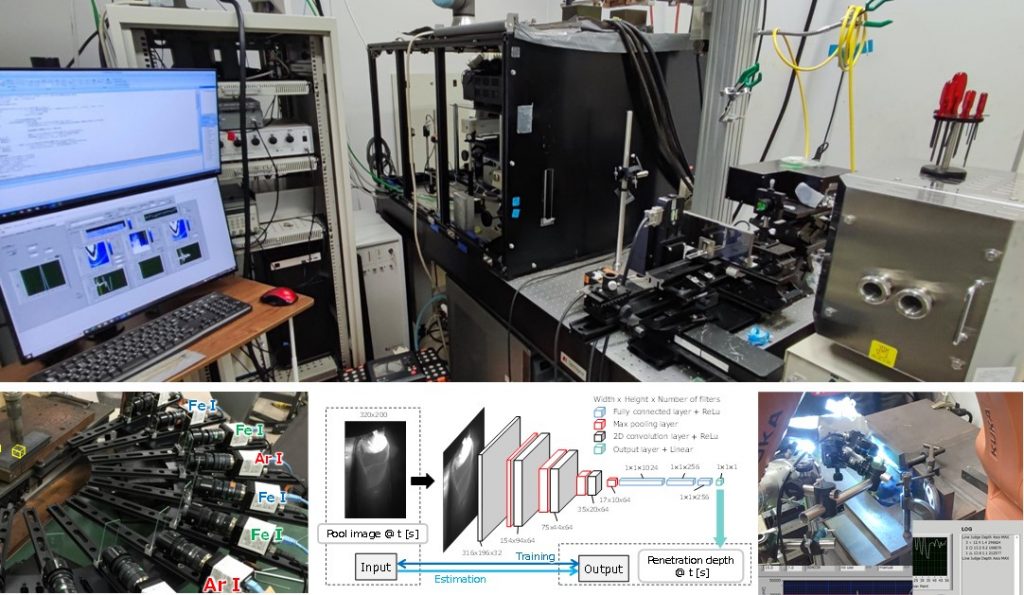

Various processes are performed at the manufacturing production site, however, inevitable disturbances may result in unintentional defects. In welding and joining, internal defects invisible from the outside occur, which deteriorates the joint performance; therefore, inspection is essential. However, there are problems such as a decrease in production efficiency due to a backtracking process after finding a defect, and the fact that some defects cannot be found because of inspection difficulty. If in-situ measuring of internal defects and in-process quality assurance are realized, a great innovation in production technology can be expected. We are studying and developing advanced measurement methods applicable to in-process as follows:

- Dynamic and non-contact in-situ ultrasonic detection by laser ultrasonic method.

- Penetration estimation that combines molten pool monitoring and AI.

Considering the strength and safety standards in the design of materials and structures, our area provides the education and research with the aim of development of the simulation and new technology based on reliability engineering for advanced material design and safety evaluation for high reliability. Furthermore, we promote the manufacturing in several fields such as medical, energy/environment, electronics, disaster prevention/risk, and engineering education through cross-disciplinary and industry-academia collaboration.

Top