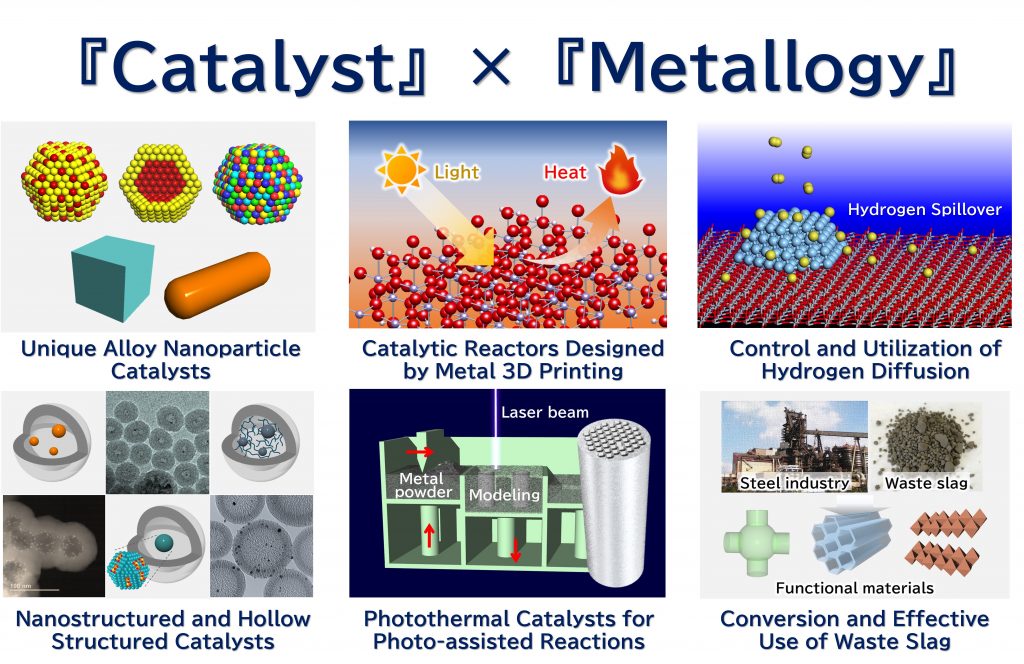

”CO2 resource technology” and “hydrogen utilization technology” are at the core of achieving carbon neutral by 2050. To achieve “revolution of energy resource”, it is essential to develop “nanostructure catalysts” precisely designed at the atomic and molecular level according to the target reaction. We are studying to create highly active and practical functional catalysts that contribute to energy creation and solving environmental problems by combining “catalyst design”, “materials science”, “advanced structural analysis technology”, and “theoretical calculation”.

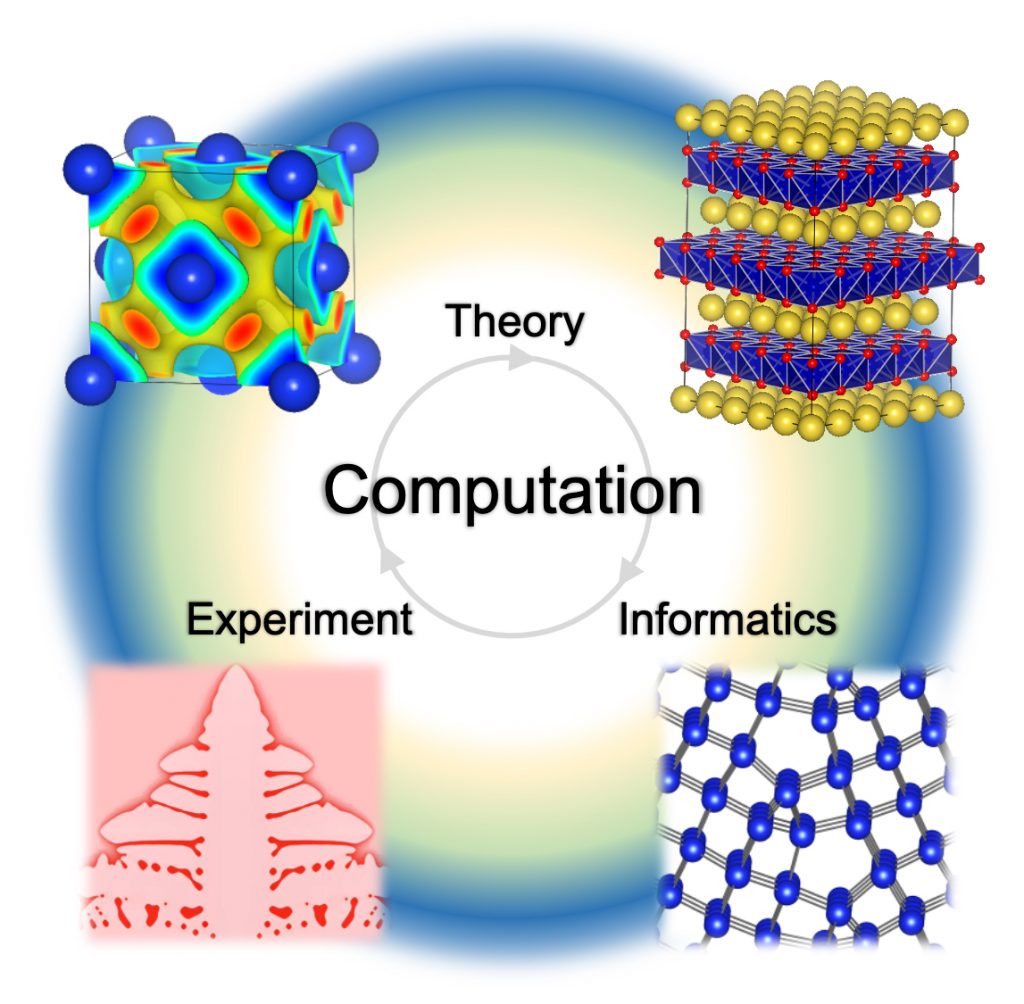

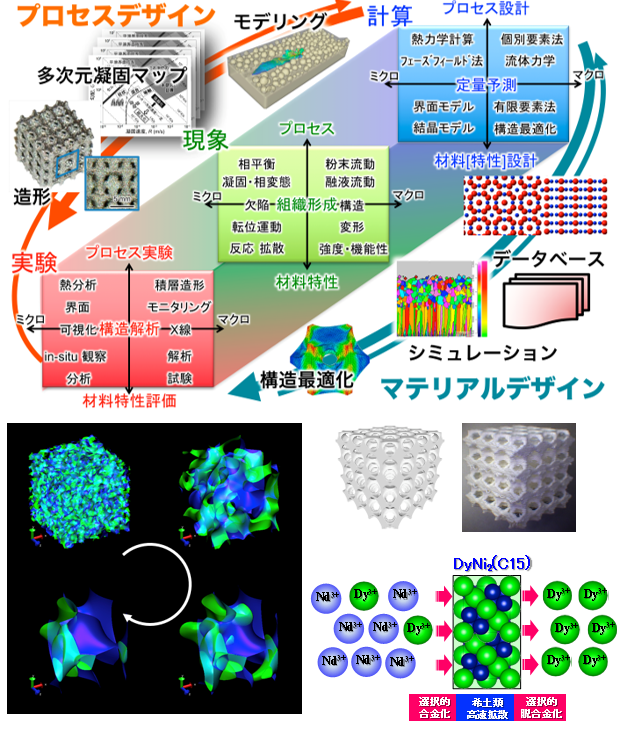

The computational approach using computers, which is called the third paradigm, is not only meeting the increasingly severe needs of society regarding materials, but is also enabling to provide seeds to society. In this laboratory, we have been developing new materials by utilizing computational materials science methods from atomic to macroscopic scales, and by organically connecting them with experiments and theories to construct new materials design strategies that are not confined to existing theories.

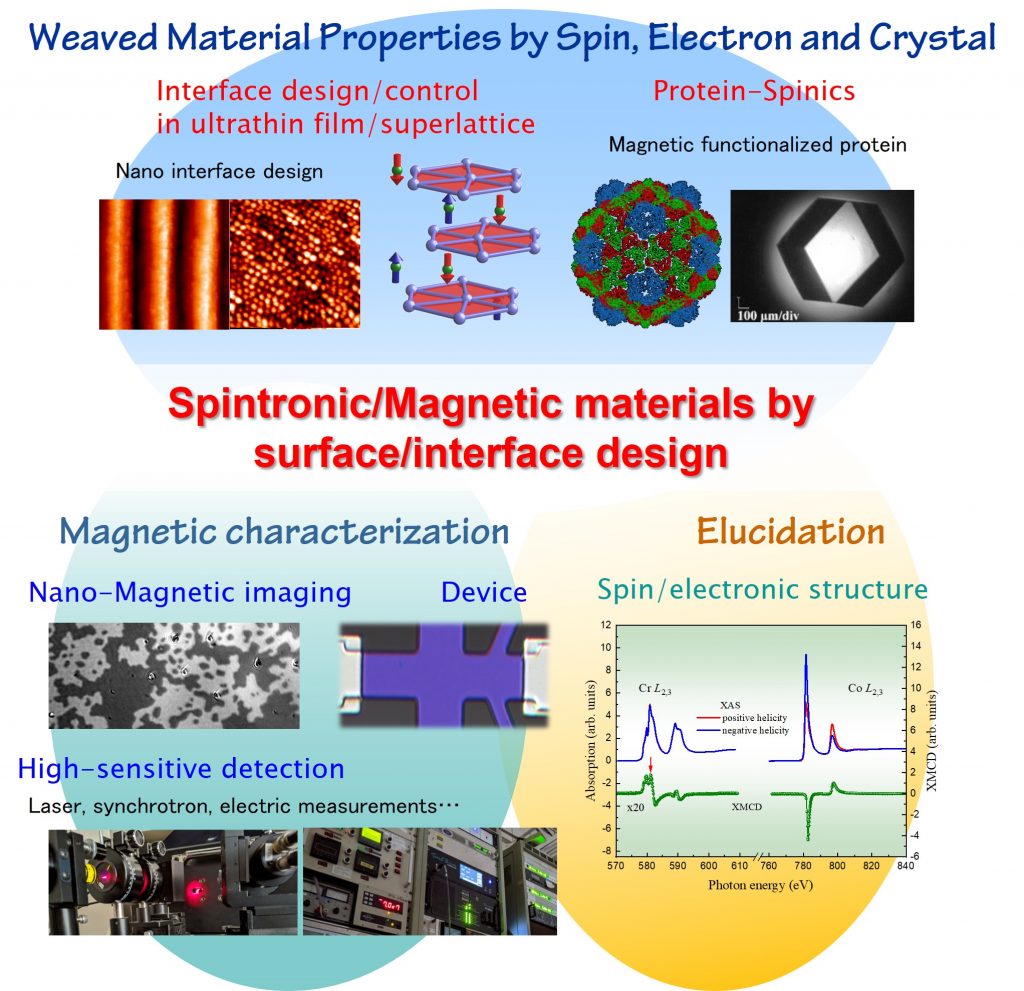

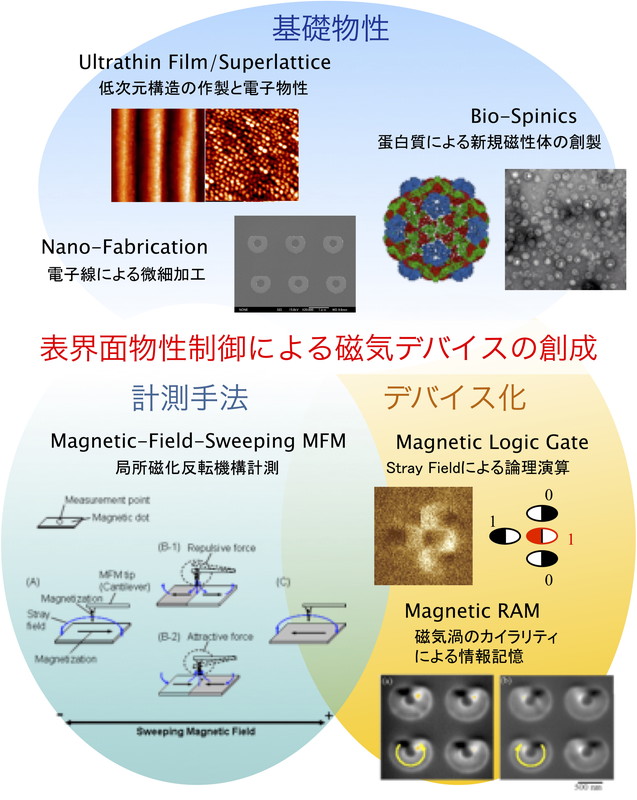

Our reseach topics is nano materials toward future electronics devices such as memory, storage and logic based on the high-quality thin film fabrication. Designing materials which do not exist naturally, fusion of electron chage and magnetism etc…, enjoy materials science in nano-world!

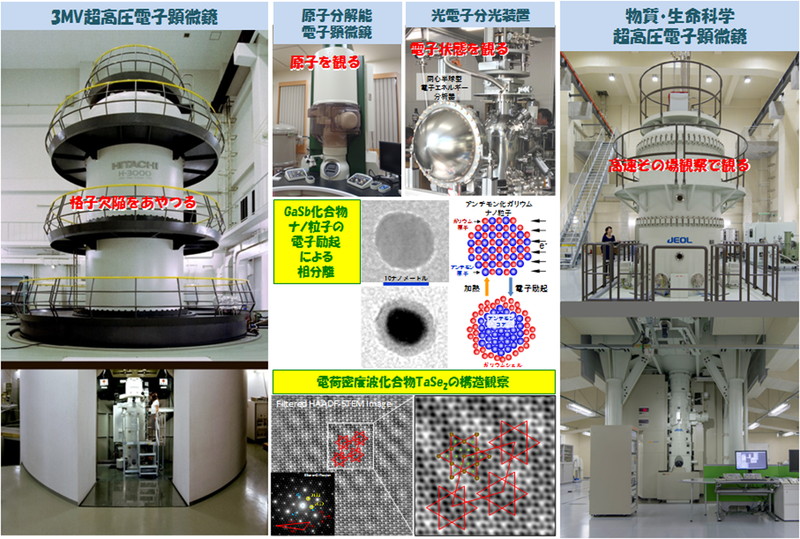

This research group is investigating the relationship between microstructures and material properties using advanced transmission electron microscopy and spectroscopy with nanometer and nanosecond scales. The research subjects include materials design by elucidating inhomogeneity such as lattice defects, low dimensional materials, metastable states formed by electronic excitations, and so on. We are conducting education and research aimed at elucidating universal common principles that approach the basis of materials science.

Positrons allow us to examine the atomic-scale internal structure of materials. We have examined the origin of excellent properties of metallic materials such as hydrogen storage alloys and aluminum alloys in automotive applications and ceramics materials such as perovskite-type metal oxides, by using positron annihilation spectroscopy and computer simulation in order to design new materials.

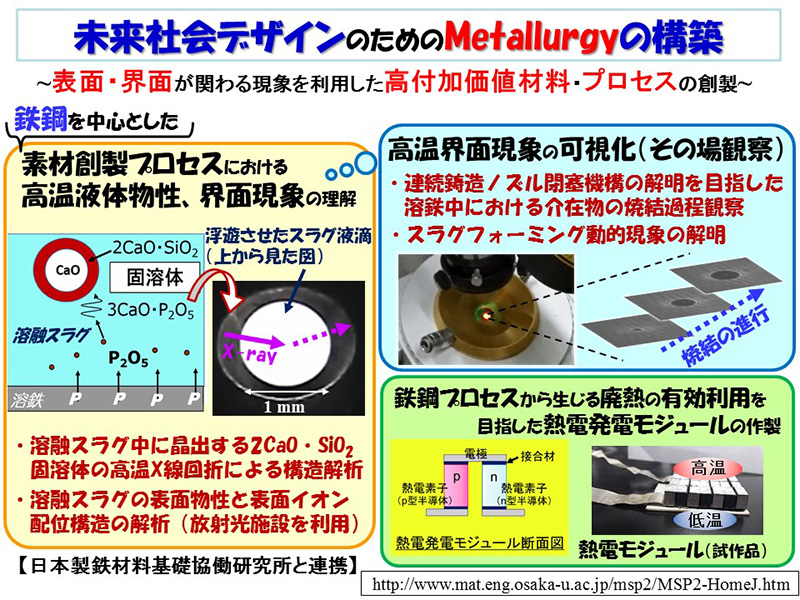

Toward the achievement of a sustainable society, we aim to develop low-carbon process for iron-steel and non-ferrous metals, and to develop processes for semiconductor materials and ceramic materials which support energy-saving technology. We design and evaluate the materials processes based on metallurgy such as thermodynamics, kinetics and high temperature melt properties. Moreover, we visualize various reaction processes using the newly-developed visualization technology.

The design of materials that exhibits desired functions and the development of their production processes have always been the foundation of manufacturing industries. Nowadays, the establishment of a sustainable society is an urgent global issue, and therefore, the reduction of environmental burdens, such as energy savings, CO2 emissions reduction, and recycling is also an important factor in material design and process development. On the other hand, the digitization of manufacturing processes, as represented by 3D printers, has brought about both new possibilities and challenges to material design and process development. There are various phenomena that can not be predicted or explained by existing science. We aim to contribute to the establishment of a sustainable society and the innovation of our daily life through the creation of new materials by novel technologises, including computer simulations and data analysis for designing materials and optimizing processes via the combination of computational techniques and experimental methods. Also, we aim to systamatize the new scientific knowledge as the metallurgy of new age.

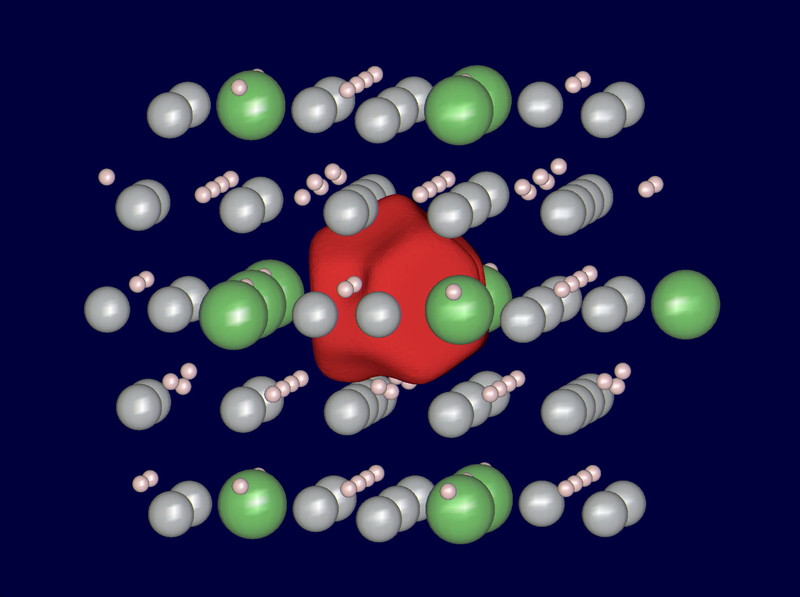

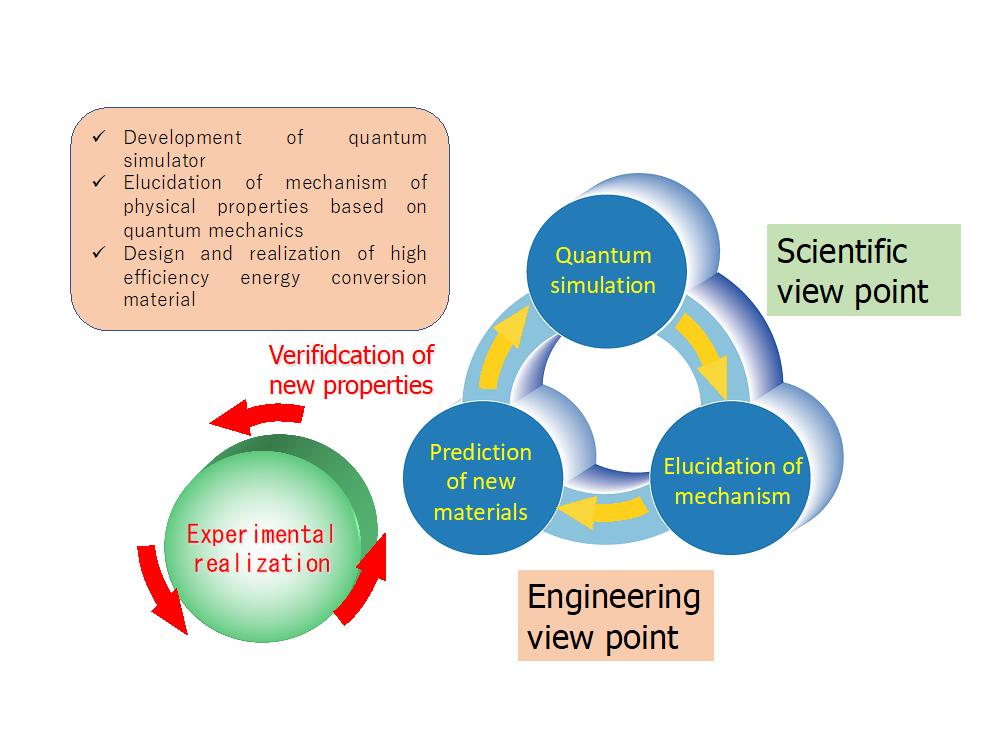

・ We provide computational materials design of functional materials and demonstrate its validity by performing experiments. Particularly, we try to describe various physical phenomena related to the electronic excitation (such as finite temperature magnetism, entropy change due to the external field, electronic, thermal and spin transport phenomena) from first-principles. To realize this purpose, we develop quantum simulation methods by combining various theoretical methods. Those methods are applied to designing materials for effective energy conversion and conservation. For providing guidelines for effective search for ideal materials, we also apply statistical data analysis to simulation and experimental results.

Research topics

・ Development of first-principles quantum simulation method

・ Computational materials design for efficient energy conversion and its demonstration, such as solar cell materials, light emitting materials, thermoelectric materials, magneto-caloric materials.

・ Computational materials design for efficient energy conservation and its demonstration, such as spintronics materials, heat-resistant and high strength materials and superconductors.

・ Computational modeling of material properties of multi-component alloys and its application for materials search.

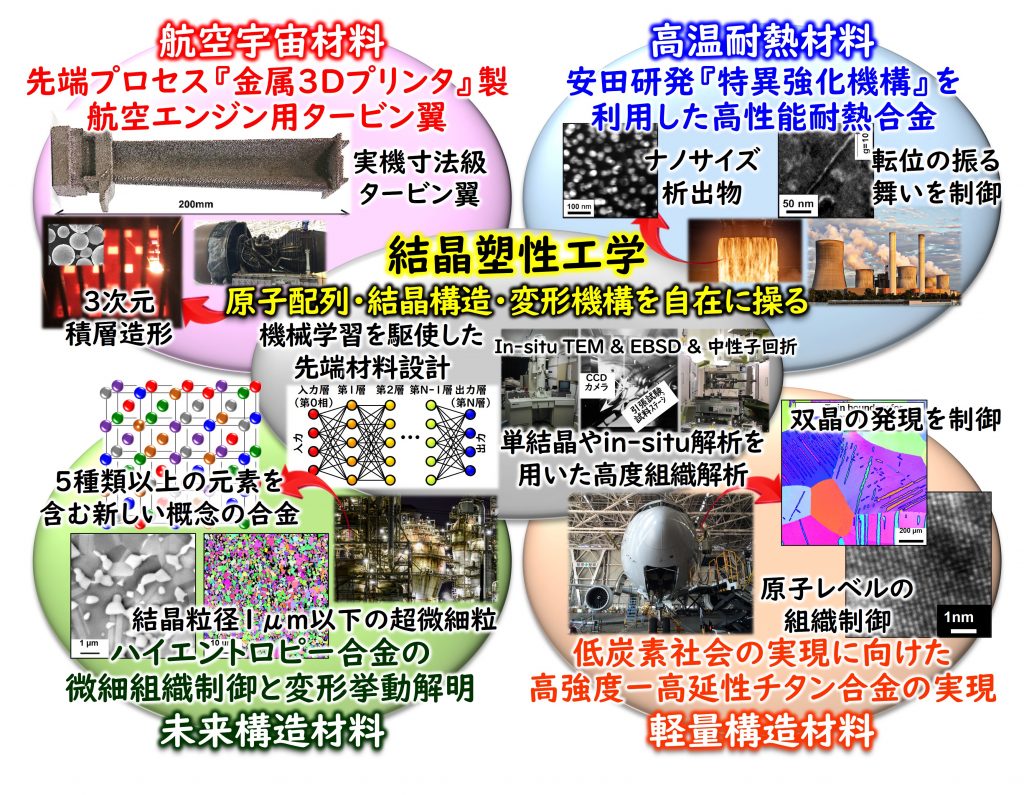

Plasticity of crystalline materials such as metals and ceramics depend strongly on behavior of lattice defects such as dislocations and grain boundaries. We aim to develop and design the advanced structural and functional materials such as heat resistant alloys, permanent magnets, superelastic alloys and metallic glass by controlling lattice defects in nano- and micro-scale.

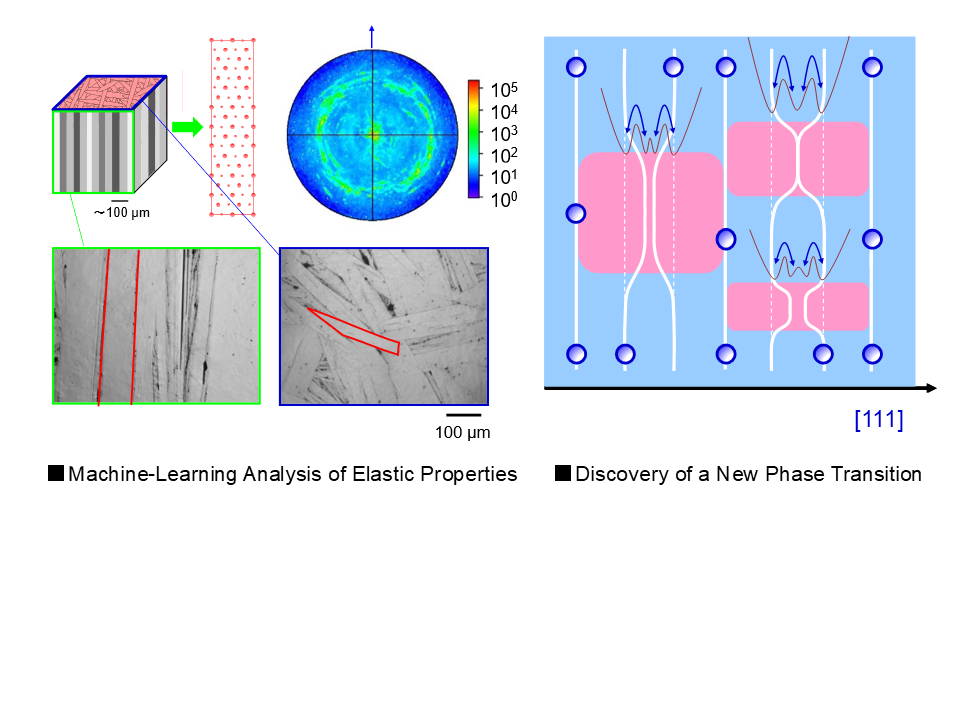

The mechanical properties of materials—such as elasticity and strength—are governed by micro- and nano-scale factors that span multiple length scales, including crystal structure, the directionality of interatomic bonding, crystallographic texture, and the morphology of two-phase microstructures. Identifying which of these factors dominate at each scale, and translating that knowledge into new design principles for achieving superior mechanical performance, is essential for the development of next-generation materials. Our group views materials as hierarchical, complex mechanical systems extending from the nanoscale to the macroscale. By combining elasticity theory, thermodynamics, and machine-learning techniques, we study the mechanics, phase transformations, and microstructural evolution of materials. Through this work we aim to establish novel design rules that will enable the creation of advanced materials for applications in biomedicine and aerospace engineering.

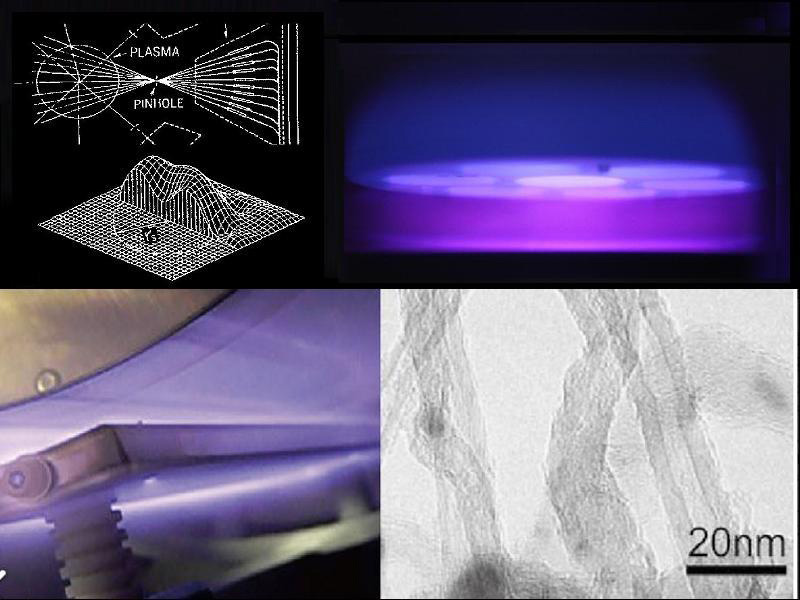

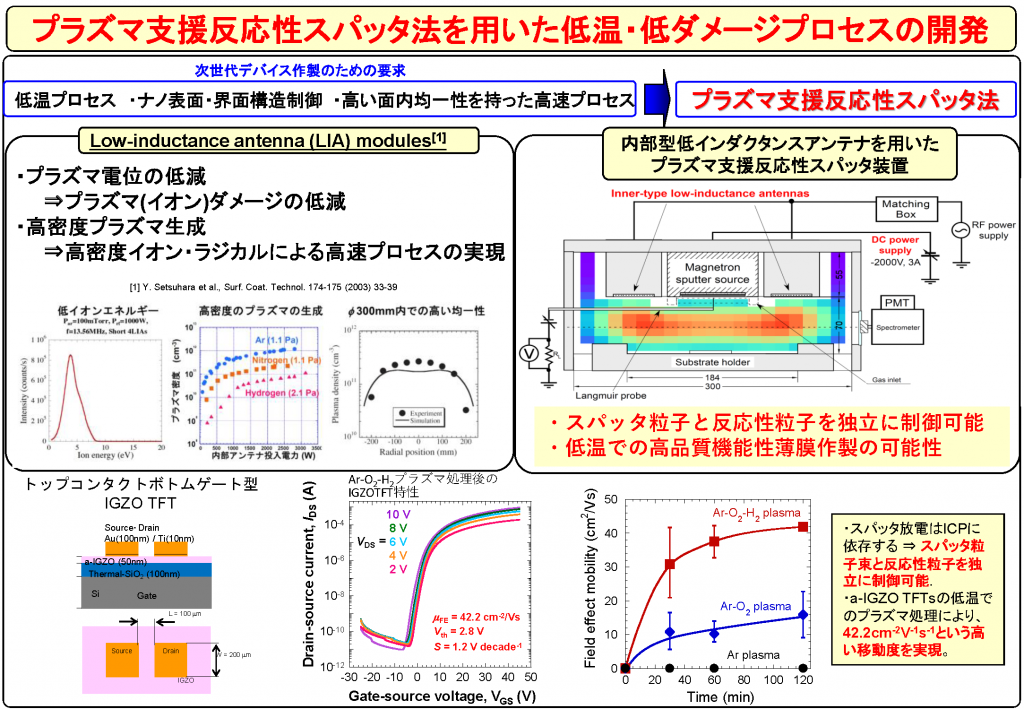

We study plasma in order to control and use it in various applications that will help the world to solve energy/biological/environmental problems. We generate various plasmas in various environments (gas, liquid, or supercritical fluid) and use advanced diagnostic methods to control and understand them. Current studies in applications include thin film deposition, surface modification, nano-structured materials synthesis, treating biological molecules, and environmental treatments.

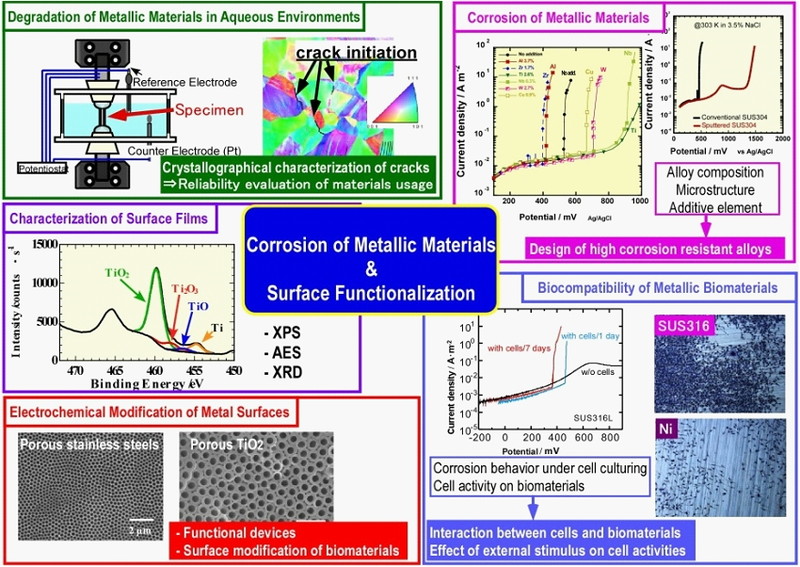

Materials deterioration and damage caused by the interactions with diversified and severe environments are one of social issues. We study the interactions between materials and environments such as aqueous environments and high-temperature atmospheres and also aim to develop new materials with high corrosion and oxidation resistance. A wide range of characterization techniques including electrochemistry is used to examine the properties of metal and semiconductor surfaces. Tailoring the interactions between materials and environments often leads to the formation of unique surface structures. We target on the fabrication of highly ordered nano-scale structured surfaces with enhanced functionalities.

Towards the realization of green/life innovations, we are challenging to clarify the mechanisms underlying the functionalization of biological tissues and organs, and further the development of innovative biomaterials and aerospace materials, based on Materials Scientific approaches. We focus on the anisotropic hierarchical microstructures that determine the mechanical functionalization in biological system and develop novel materials which can realize superior functions even under extreme environment involving biological conditions, super high temperature by using additive manufacturing (AM) and computer simulation technologies. The aim of our research is to develop a new scientific principle “Materials Science for Anisotropy”.

Control of Materials Function and Morphology Area

This laboratory is developing novel processes for new materials such as eco-materials, high-strength materials, materials with formability. The evolutions of microstructure, texture and properties during the processes are investigated academically. Tribology in the process is also studied.

From the perspective of fundamental properties of surface/interface physics, we have performed education and researches to improve the electron-determinate functionalities, including magnetism/electron transport/tunneling properties, of nanomaterials; metallic thin layers/multilayer films/artificial lattices/nano-magnets.

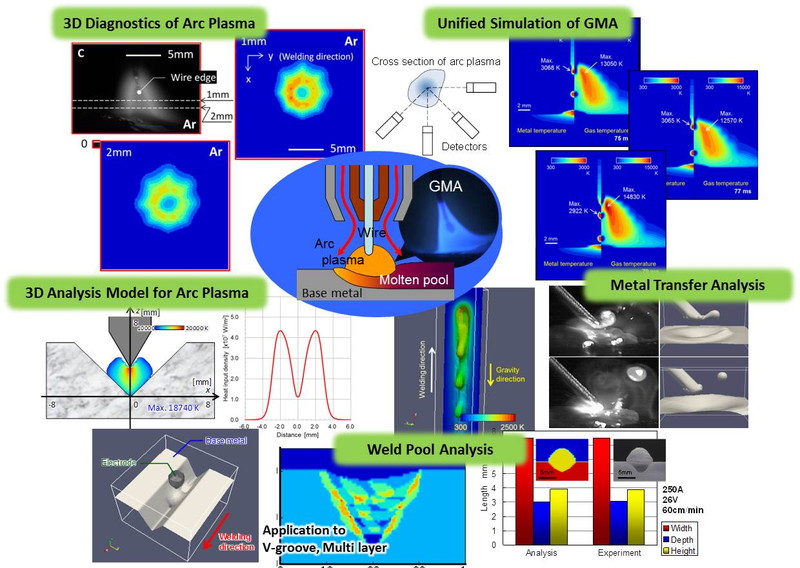

We are promoting studies to elucidate, predict, and control the phenomena in materials processing using laser and plasma based on the physics of the process by combining and making full use of an advanced measurement and a numerical simulation technology. Utilizing the knowledge obtained, we aim to develop a unprecedented process based on the universal truth.

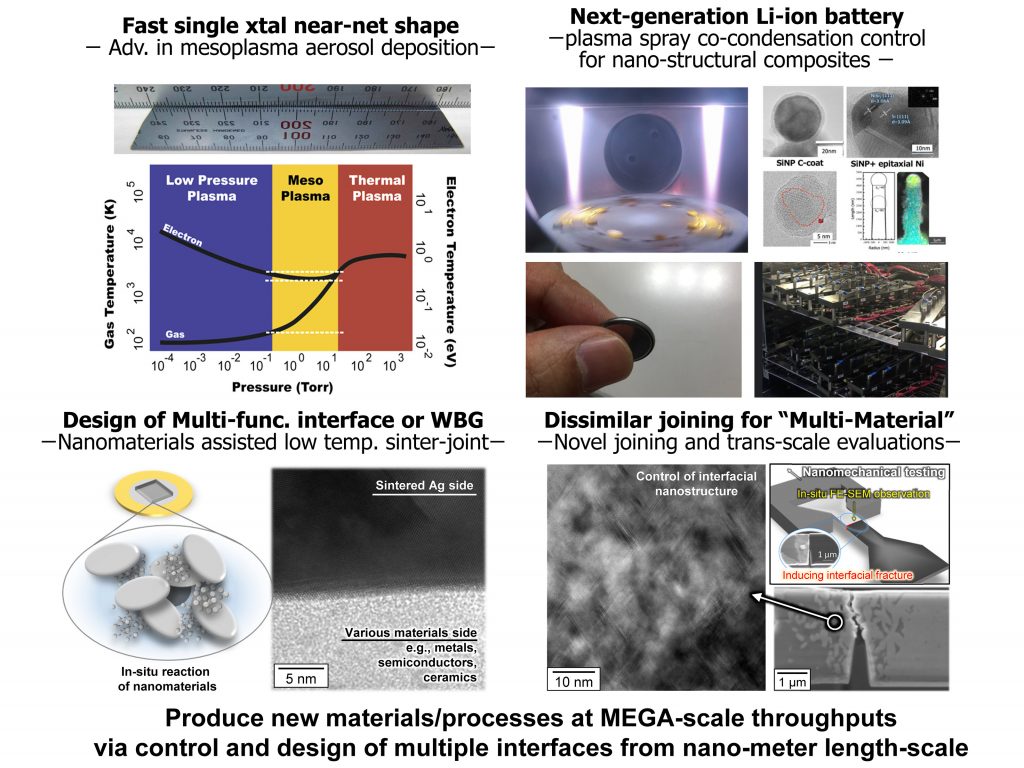

To respond to technological demands for development of future society, mission of our lab is to aim at advancement in materials design and processing, baring in mind the nano-meter length scale structural/interface control at affordable MEGA-scale production. In particular, making the best of and advancing the knowledge “Plasma Materials Engineering”, we challenge to propose novel materials/processing that attain both high quality and low-cost, multi-functionality and low environmental load simultaneously. Current research targets include; control of plasma spray co-condensation for nano-composite materials production for next-generation all-solid state lithium-ion batteries, design of multi-functional interface and development of low-temperature nanoparticle-assisted sinter-joint for wide-bandgap power device, development of dissimilar material joints to proceed “multi-material” technologies.

To advance the material science research in welding/joining, 1) Clarifying the multi-scale material behaviors for visualization comprehension with atomistic approach, 2) Evolving the interfacial bonding for material science approach to advanced materials & processes, 3) Promoting the collaborative research in material mechanics process for comprehension & prediction of welding/joining phenomena. Our mission is to systematize the “Processing Metallurgy” for optimizing the welding/joining/repair/maintenance processes.

Process Metallurgy Area

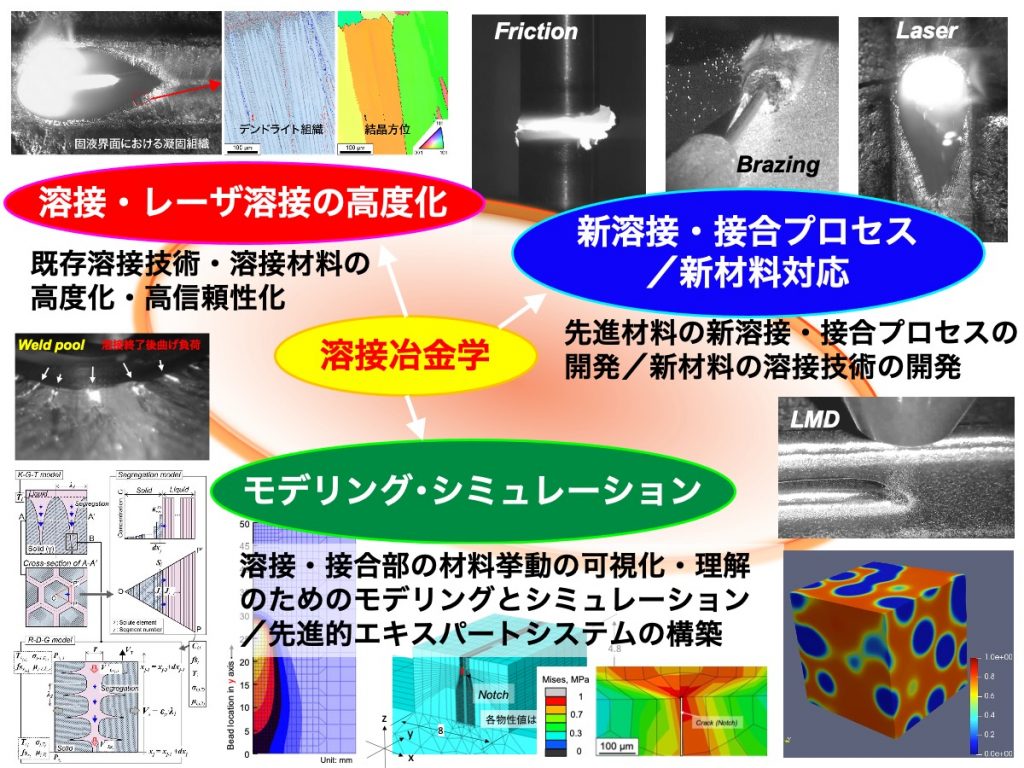

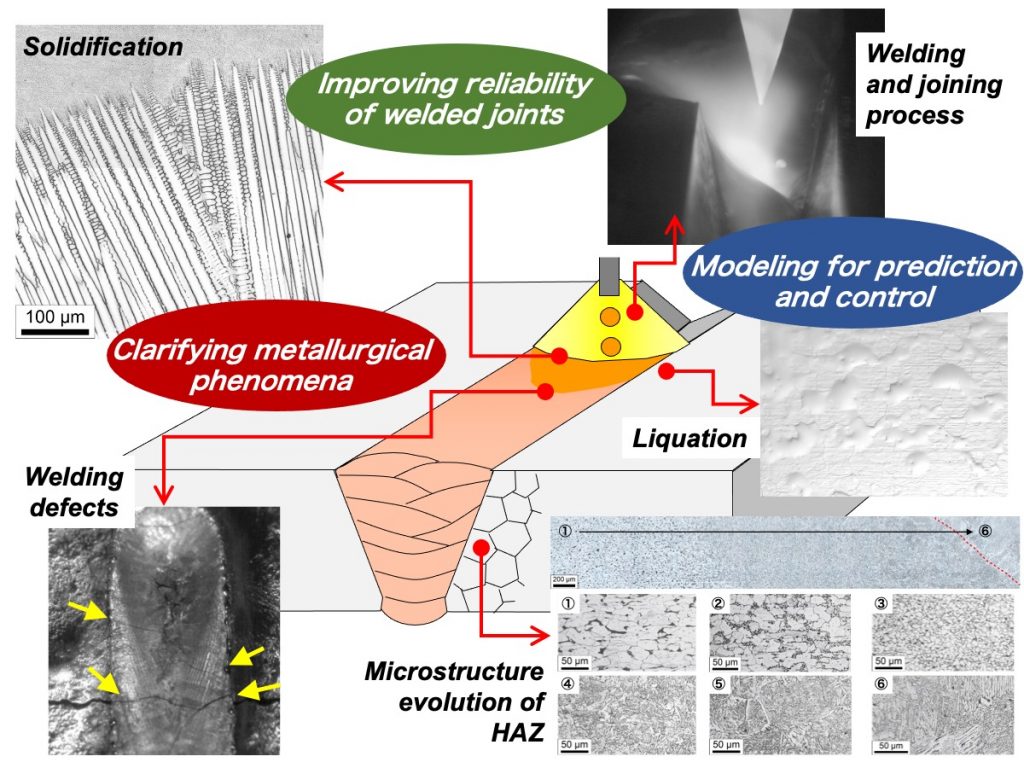

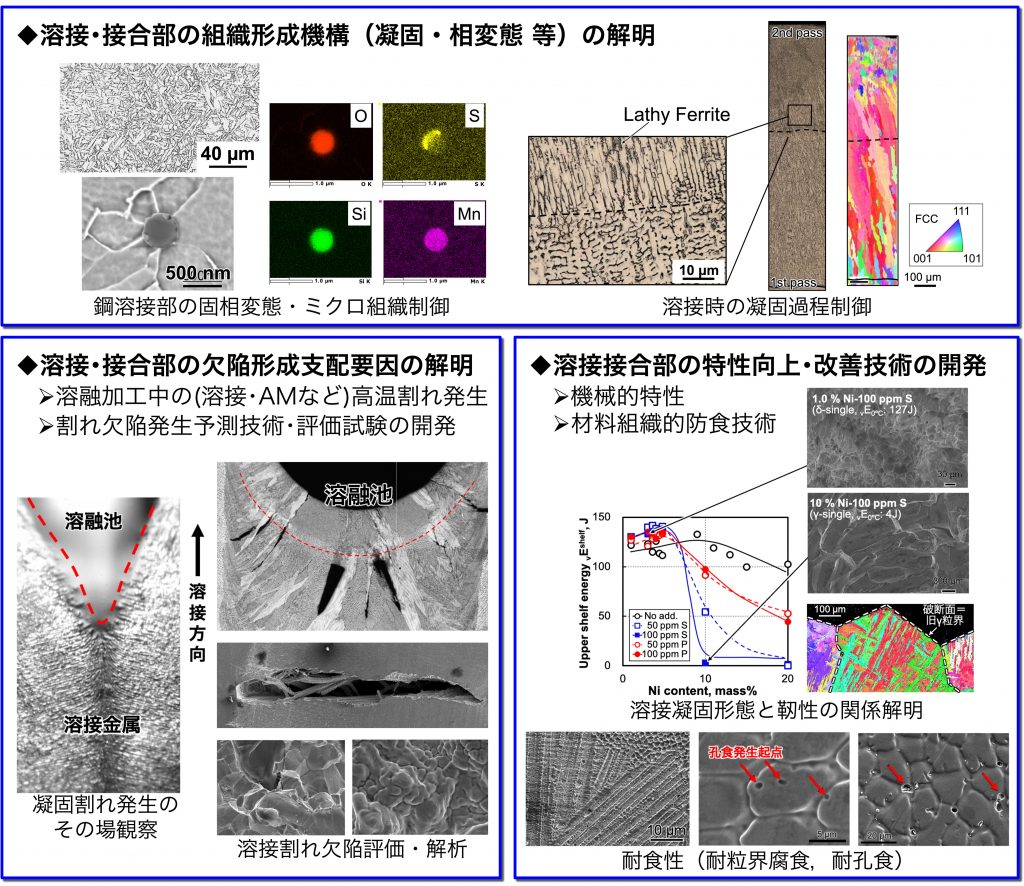

Aiming to sophisticate the research of welding metallurgy, we are promoting (1) to clarify the metallurgical phenomena during welding and joining process, (2) to model it for prediction and control and (3) to improve the welded joint properties, cooperating with Welding and Joining Process Area.

Aiming at technological innovations in processing of state-of-the-art semiconductor devices and biomaterials, we conduct research in plasma physics, plasma chemistry, and plasma-material interactions, using experiments, modeling, and numerical simulations. We perform multi-disciplinary collaborations with various research groups/institutes, including medical schools and private companies, in international research networks.

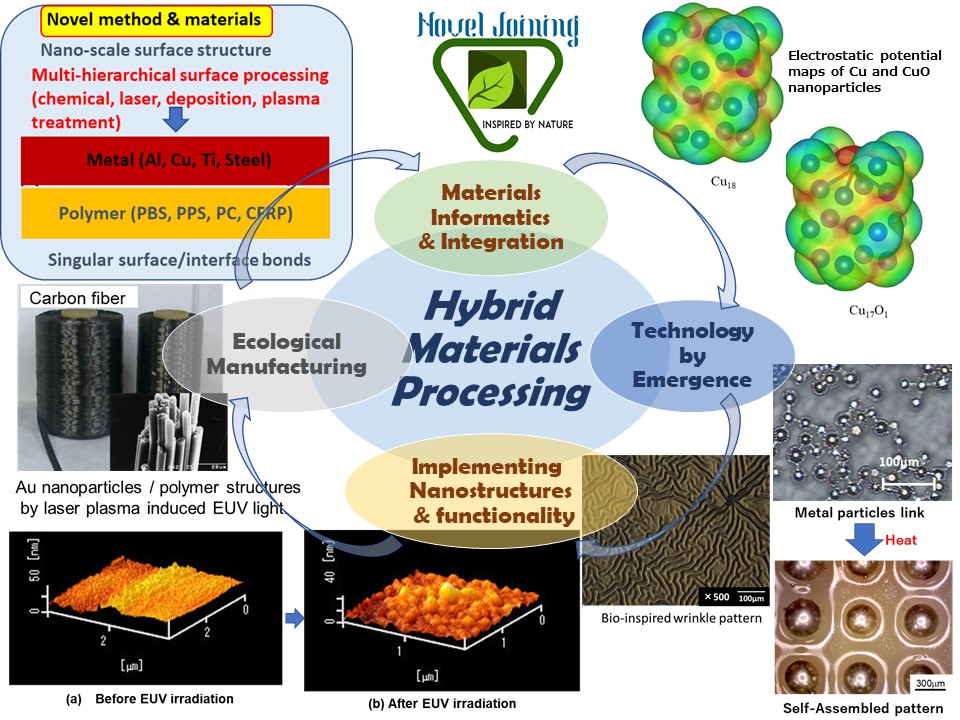

For a low-carbon society, we develop biomimetic materials and manufacturing processes that weave together “engineering knowledge” and “biological knowledge” that humans and nature have accumulated. Our research consists of three main pillars; Development and application of nanomaterials that realize energy saving and energy creation through data science, Multi-materials technology that “connects and disconnects” materials with completely different properties, Nano/micro joining of electronic materials and advanced semiconductor packaging. By making full use of theory, experiments, and simulations of manufacturing process from atomic/molecular bonding to multi-materialization, we will evolve hybrid materials and manufacturing technologies that will bring about innovations in future manufacturing “Monodukuri”.

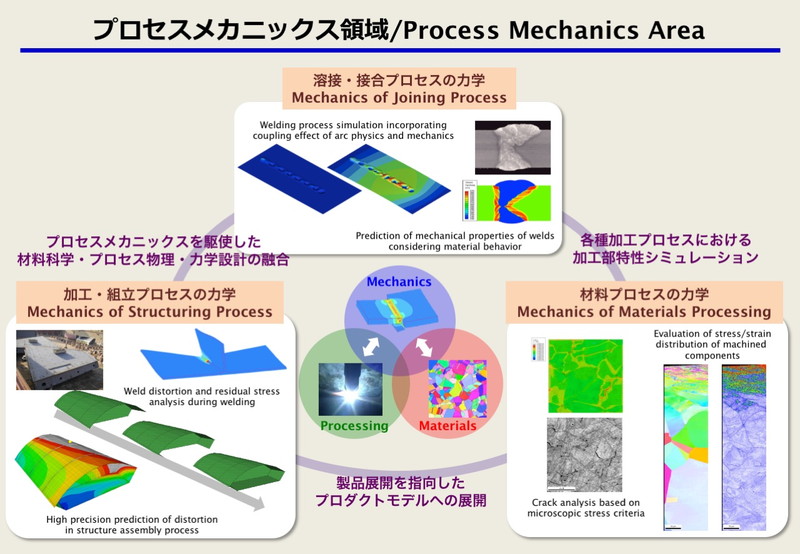

Welding and joining, cutting, machining —essential processing technologies for manufacturing—inevitably generate residual stresses and distortions, and consequently control the performance and integrity of products and structures. “Process Mechanics” is a new discipline to investigate the mechanical behavior related to manufacturing processes on the basis of materials science, physics of processes, and mechanics. Our major approaches are the development of simulation models for manufacturing processes and their application to the prediction of mechanical properties, design, and integrity assessment of components and structures.

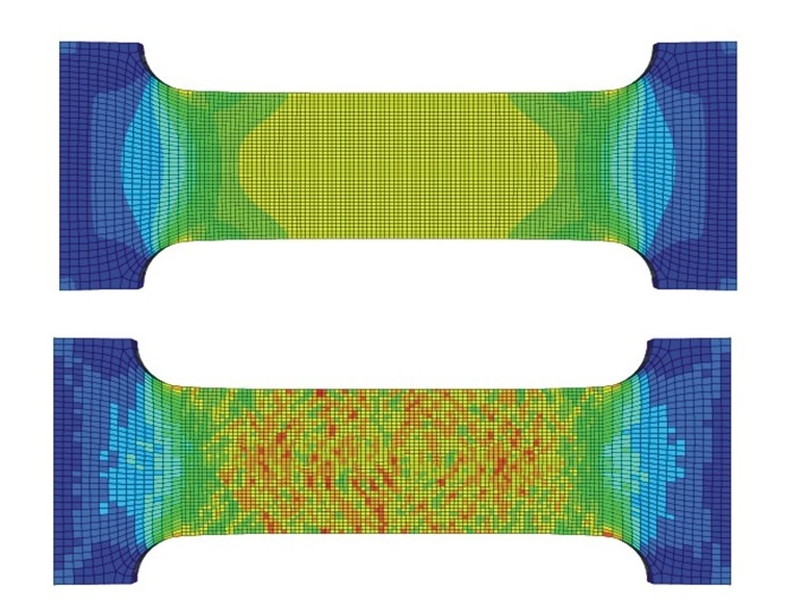

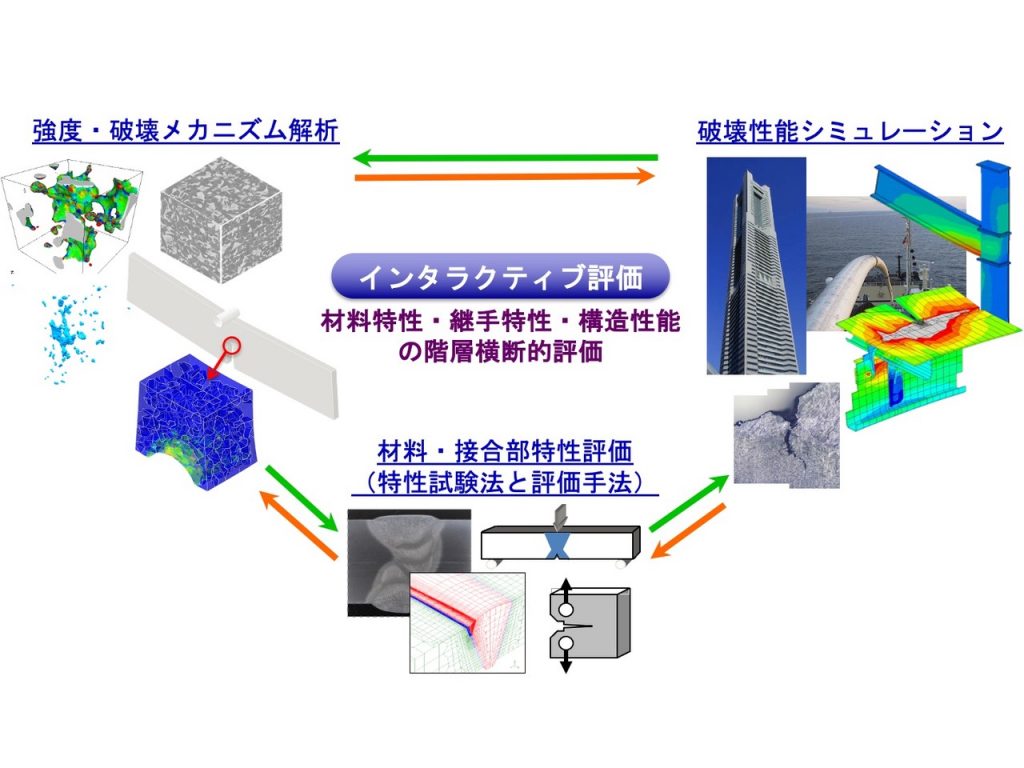

A procedure has been developing for the transferability analysis of the micro-structural properties of materials, strength of welded joints and the fracture performance of structural components, which leads to advanced multi-scale design of infrastructures as well as industrial goods. The study includes the mechanics and mechanism of ductile damage, brittle fracture and fatigue of structural steels. A computational damage simulation with modeling damage and fracture is on going, which enables the link between the materials properties and the structural integrity in terms of the resistance to unstable fracture, crack growth resistance, ductile instability and fatigue fracture.

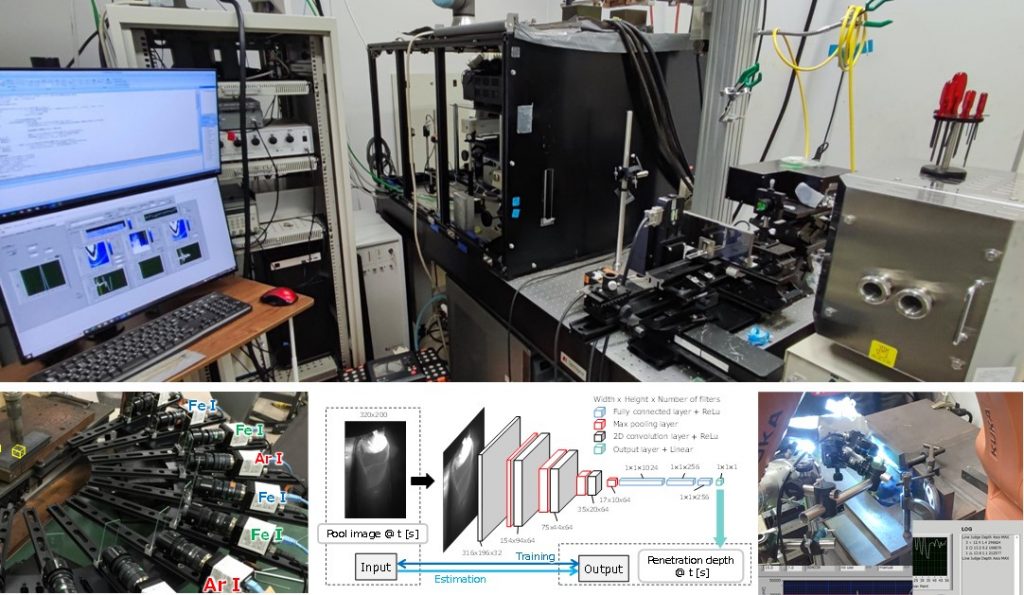

Various processes are performed at the manufacturing production site, however, inevitable disturbances may result in unintentional defects. In welding and joining, internal defects invisible from the outside occur, which deteriorates the joint performance; therefore, inspection is essential. However, there are problems such as a decrease in production efficiency due to a backtracking process after finding a defect, and the fact that some defects cannot be found because of inspection difficulty. If in-situ measuring of internal defects and in-process quality assurance are realized, a great innovation in production technology can be expected. We are studying and developing advanced measurement methods applicable to in-process as follows:

- Dynamic and non-contact in-situ ultrasonic detection by laser ultrasonic method.

- Penetration estimation that combines molten pool monitoring and AI.

Considering the strength and safety standards in the design of materials and structures, our area provides the education and research with the aim of development of the simulation and new technology based on reliability engineering for advanced material design and safety evaluation for high reliability. Furthermore, we promote the manufacturing in several fields such as medical, energy/environment, electronics, disaster prevention/risk, and engineering education through cross-disciplinary and industry-academia collaboration.

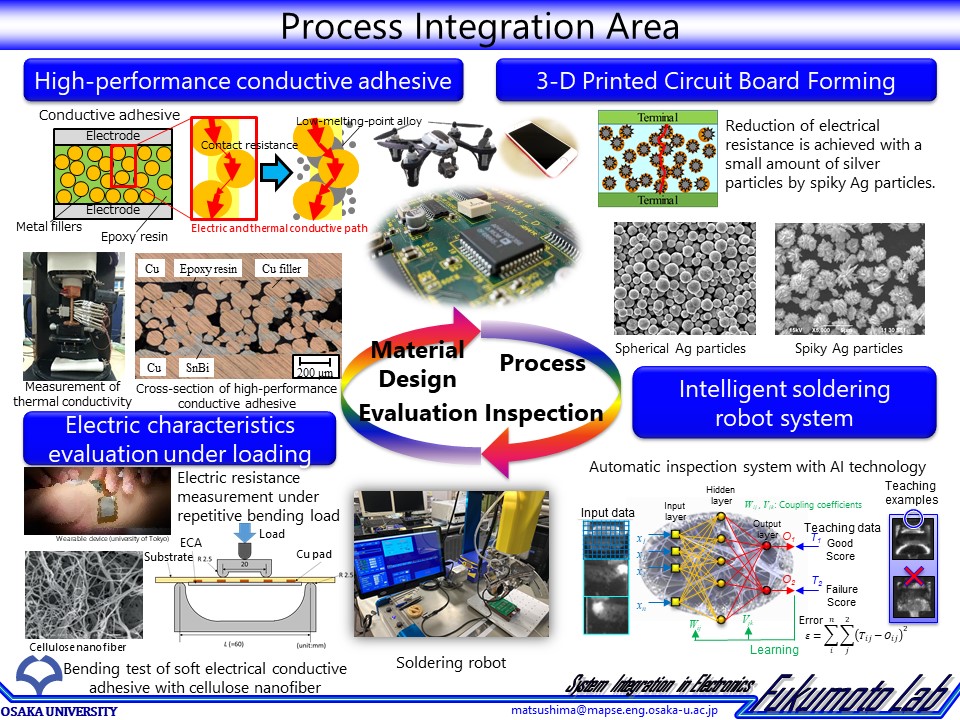

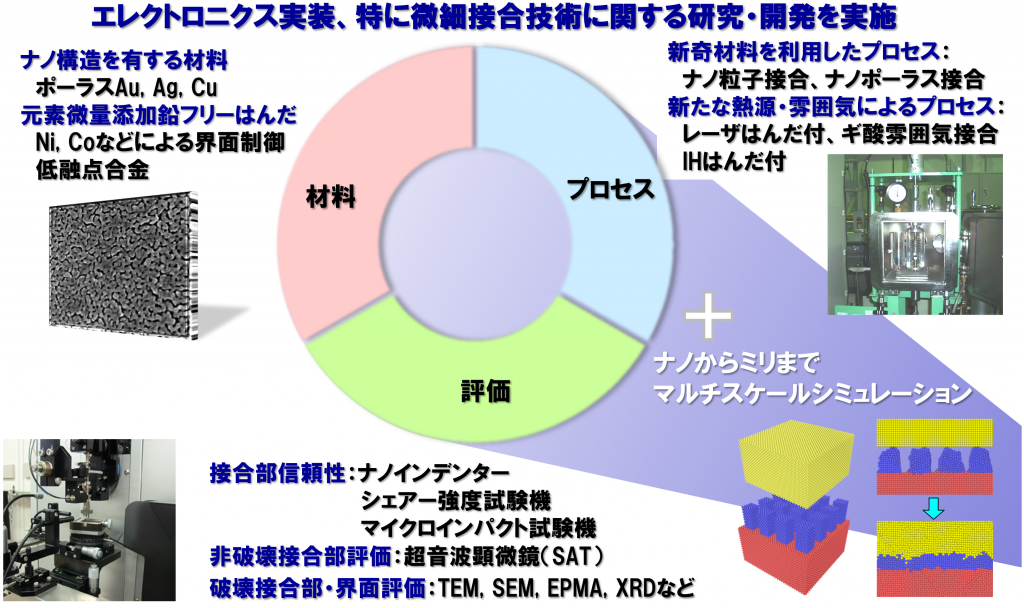

The creation of microsystems is necessary to build a safe and secure society in the advanced information age. In this area, we conduct education and research based on physical and chemical phenomena from the viewpoint of integrated process design of electronic devices, such as development of nano- and micro-dissimilar materials bonding process, design of dissimilar materials interface, development of materials for electronic devices, AI robot inspection and reliability of electronic devices.

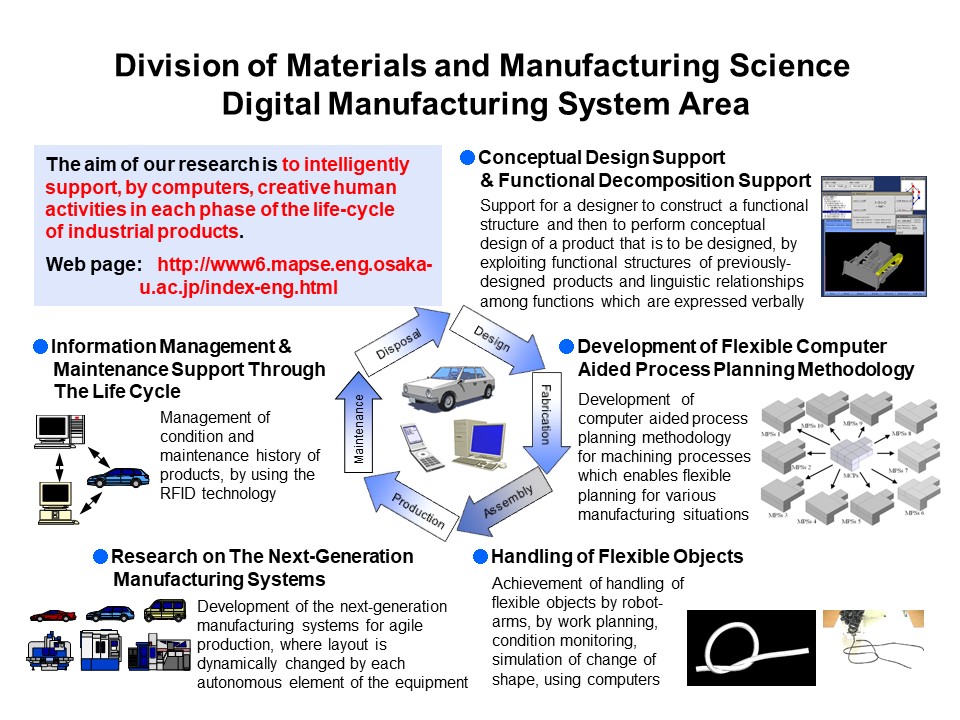

We aim to develop a methodology for intelligent support with a computer of creative human activities performed in development and production of industrial products. We have been developing computer support methods for prediction of failure occurrence during product use at the conceptual design stage, approximate stress analysis of mechanical parts using minimum training data, design and manipulation planning of flexible structures based on simulation, support with the artificial intelligence of construction and operation of the overall optimized production system etc. so that unexperienced workers can adequately perform those creative activities.

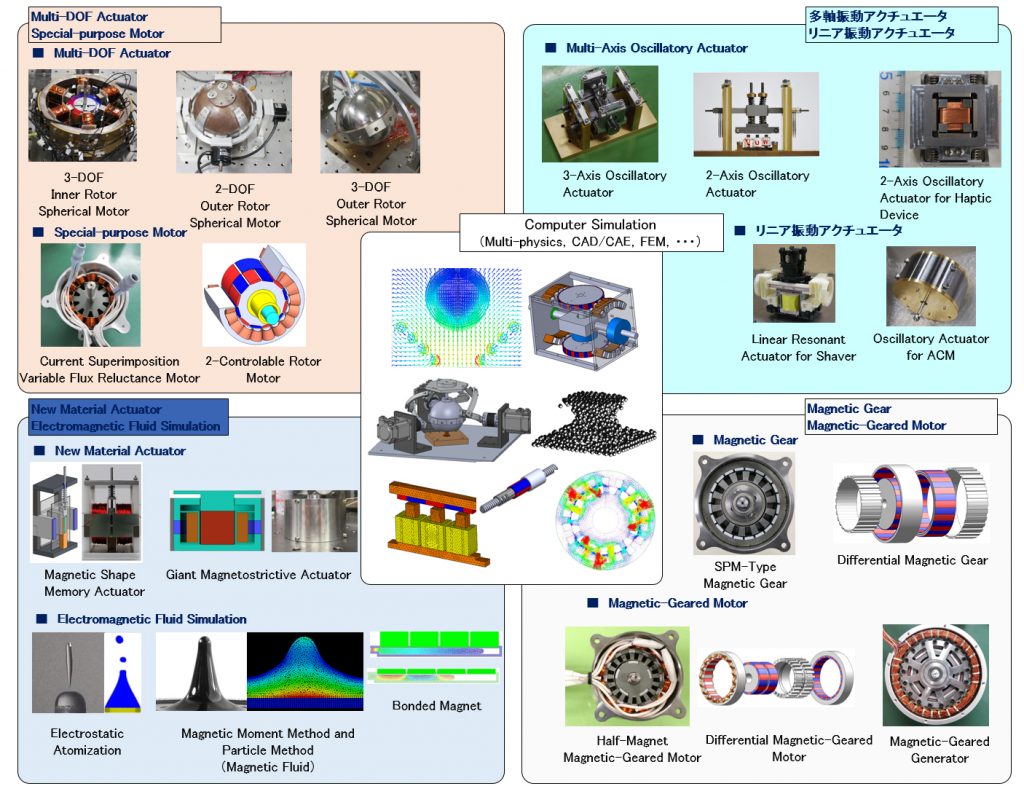

Actuators and sensor technologies are essential in science and industry for the creation of robots, automobiles, home electronics etc. We are conducting research on cutting-edge, next generation actuators and sensor devices that uses new operating principles and new materials. Examples of some of the research and education being conducted include multiple degrees of freedom actuators, linear actuators that are modeled after the human wrist, contactless torque transmitting magnetic gears, magnetic fluids, giant megnetostrictive elements, thermo-sensitive magnetic materials, and nano ion devices.

In doing research on said devices, we are also developing various coupled computational analysis methods. We aim to elucidate the mechanism of complex systems in coupled physics phenomena that include electromagnetics, mechanics, thermodynamics, and fluids by using the Finite Element Method (FEM) and Moving Particle Semi-implicit method (MPS). Based on the analysis results, we determine the optimum design parameters, and evaluate the best control method for our prototype.

At Hirata Lab, it is our policy that members are involved in the entire process of creating the new device; from the idea proposal, to the analysis method development, design optimization, prototype making, control method development etc.

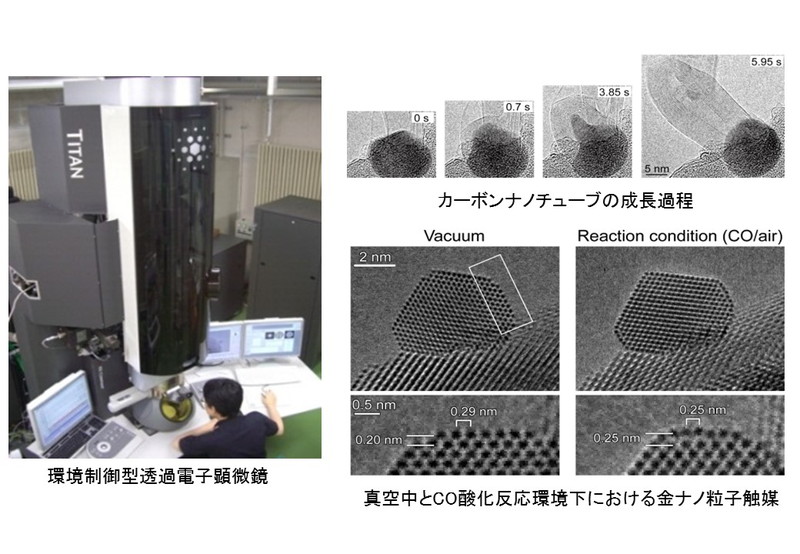

It is crucial to characterize both the fabrication processes and the properties of nanomaterials and devices at real environments. We have been developing electron microscopy techniques for the purposes. High-resolution environmental transmission electron microscopy (ETEM) now allows us to observe various dynamic phenomena in-situ and at atomic scale. With the experimental technique, we aim at creating novel nanostructures and investigating the structures and properties of the nanostructures in real environment for further progress on materials science and technology to the future.

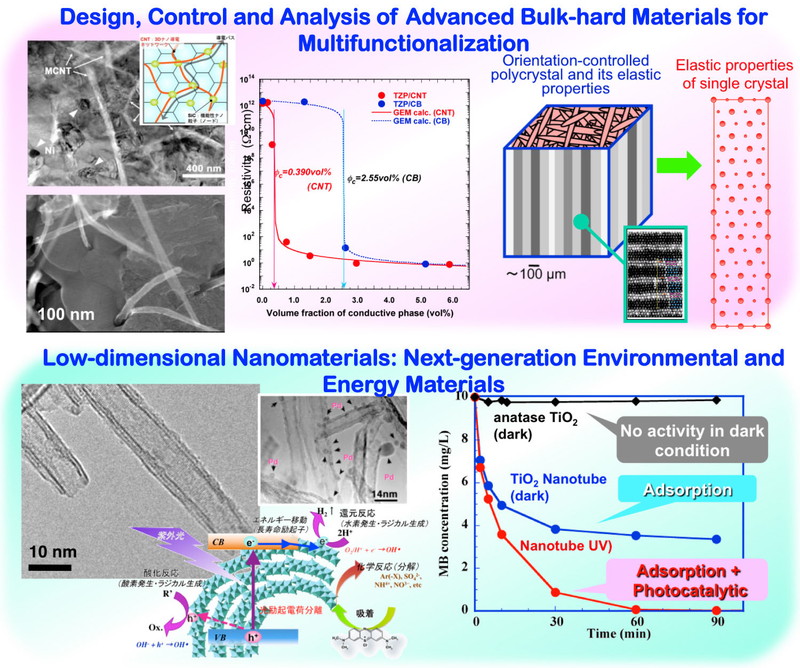

This laboratory is carrying out next-generation materials research and development of ceramics, metals and related materials from crosscutting point of view. The subject covers crystal structures, nano to macro scale hierarchical structural design and process control, fusion of various functions, and fundamental understanding of materials characteristics for advanced hard and nanostructured materials. Our emphasis is placed also on the practical application of developed materials and technologies as the key components for various devices and instruments, next generation biocompatible, environmental and energy systems, all which are the strongly demanded materials technologies to solve crucial problems arising in our society.

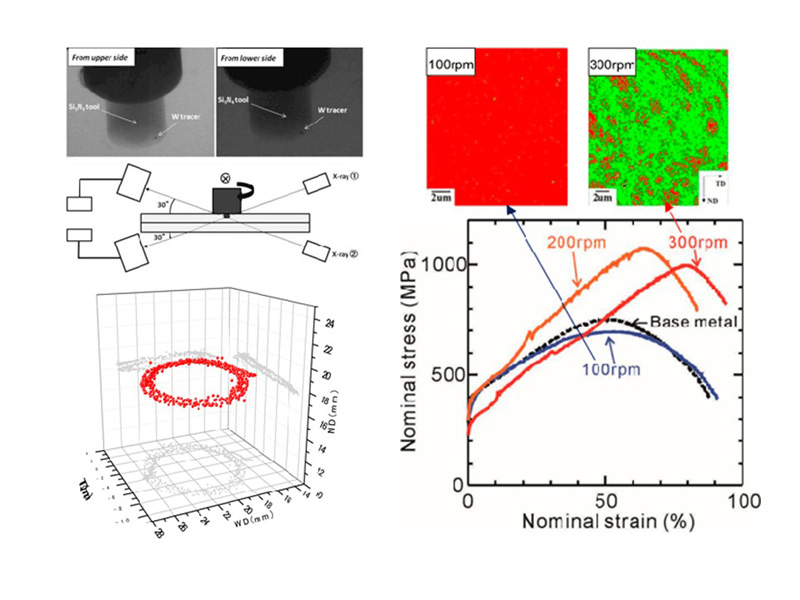

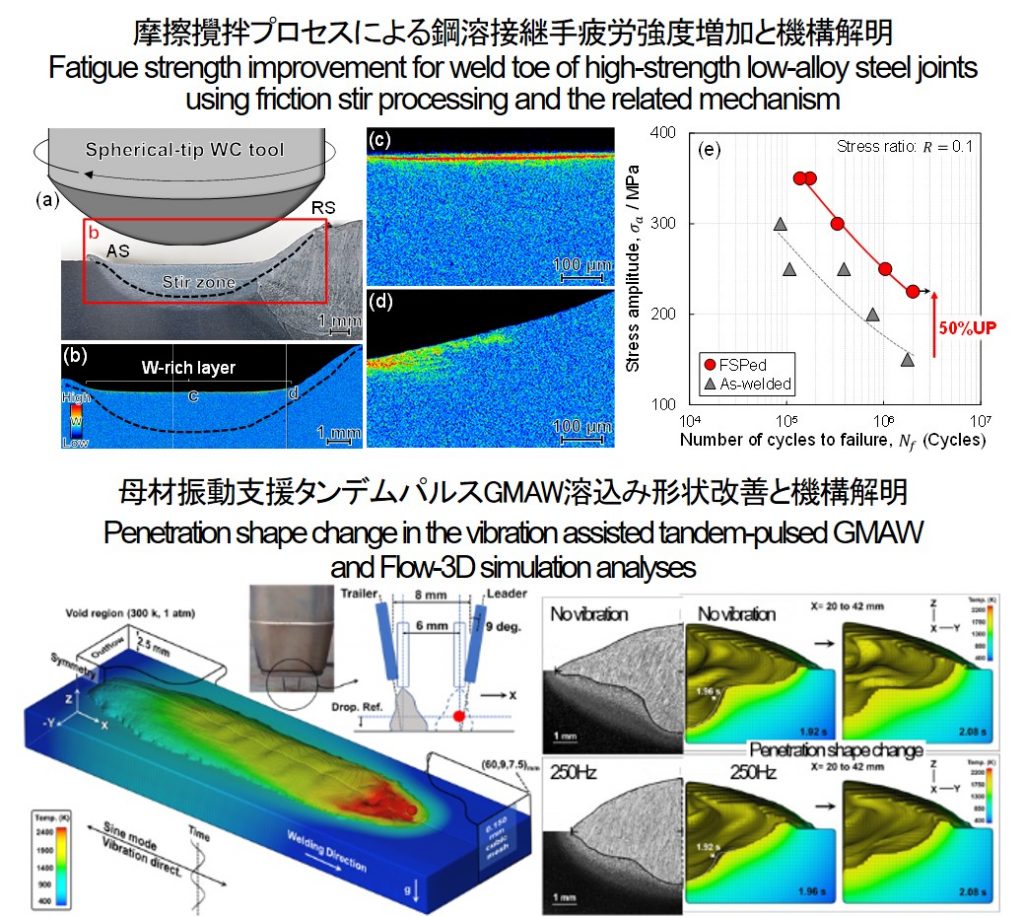

In this department, based on the elucidation of various phenomena at the joint interfaces, the interface formation mechanisms during various welding processes are clarified to create new interface control methods. In addition, novel welding and modification processes are developed, mainly based on fusion welding methods and friction welding methods such as friction stir welding, rotary friction welding, linear friction welding and linear friction stir welding methods. These developments are going to be used and focused simultaneously in our society in order to create a new research field and elevate the growth of industrial competitiveness of our country.

Energy Transfer Dynamics[Joining and Welding Research Institute]

Materials Performance and Design in Welding and Joining Area[Joining and Welding Research Institute]

Mechanisms controlling the joint performance of structural and functional materials, which obtained by fusion welding, liquid-state/solid-state bonding, and solid-state bonding, are metallographically characterized to establish a scientific basis to produce joint materials featuring superior performance. The microstructures of the weld-deposited metal, the heat-affected zone of fusion-welded joints, and the interfacial region of solid-state bounded joint are thoroughly investigated utilizing various methods such as X-ray diffraction, electron-microscopy observation, elementary analysis, EBSP analysis, and numerical modeling and simulation. Formation processes of the microstructures and their relation to joint performance are discussed from the material scientific viewpoint.

The main research subject is the development of the high density energy source for processing advanced materials having special functions and properties. We undertake fundamental investigations of the properties of the high energy source interacting with materials, and we study advanced control techniques for optimizing the energy transport. Major emphasis is placed on the generation, control and energy transport in arc plasmas, which are a high density energy source which have been applied to a variety of materials processing techniques such as welding, cutting, heating, high temperature processing, surface modification and the creation of powders.

The main research objectives are for electronics packaging to develop advanced joint materials, to establish advanced micro joining processes, and to elucidate the mechanisms of the micro joining processes. Especially, the creation of the functional joint materials, the development of novel advanced micro processes by various energy sources, the understanding of interfacial behaviors in nano-/micro-scale, and the enhancement of the highly reliable joints based on the control of interfacial structure and performance are performed.

Development of innovative manufacturing technology is required to manufacture high-performance machine products and structures of the next-generation. Department of Reliability Evaluation & Simulation conducts research and education for elucidation and control of the factors on weldment properties by high accurate evaluation based on material science and engineering. In order to create innovative and attractive technique of welding & Joining as a final aim, our department are working on elucidation of metallurgical phenomenon such as solidification and transformation, and on developing the predication method for the microstructures and the properties of weldments.

Top