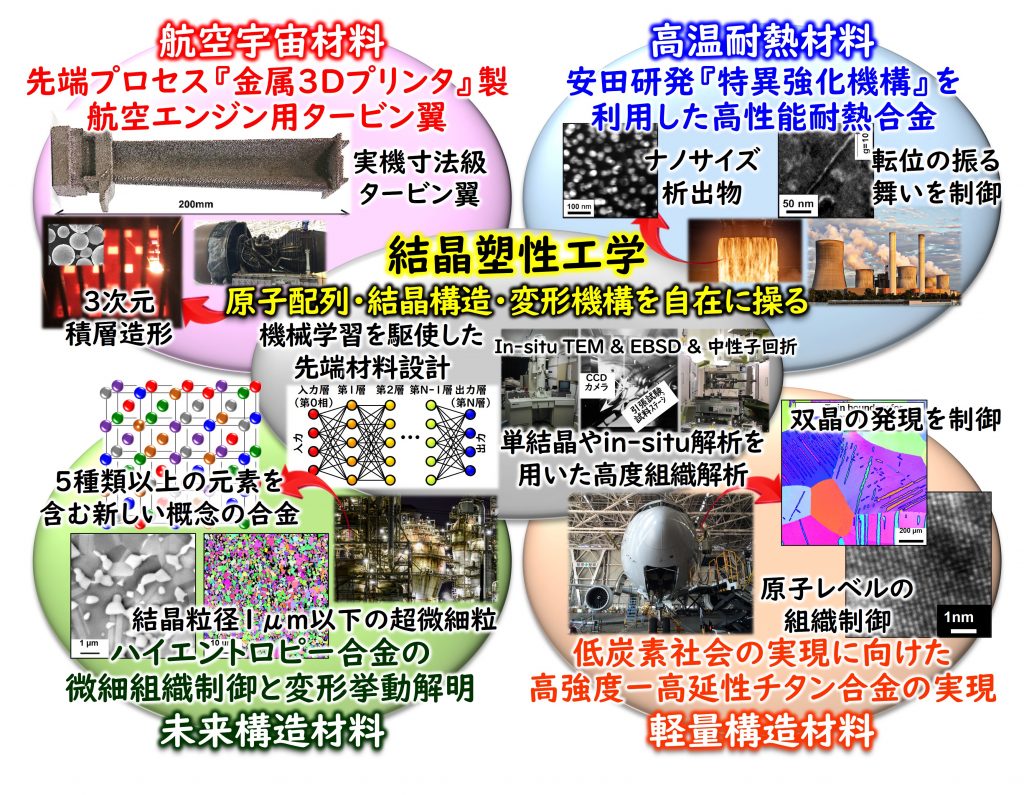

Plasticity of crystalline materials such as metals and ceramics depend strongly on behavior of lattice defects such as dislocations and grain boundaries. We aim to develop and design the advanced structural and functional materials such as heat resistant alloys, permanent magnets, superelastic alloys and metallic glass by controlling lattice defects in nano- and micro-scale.

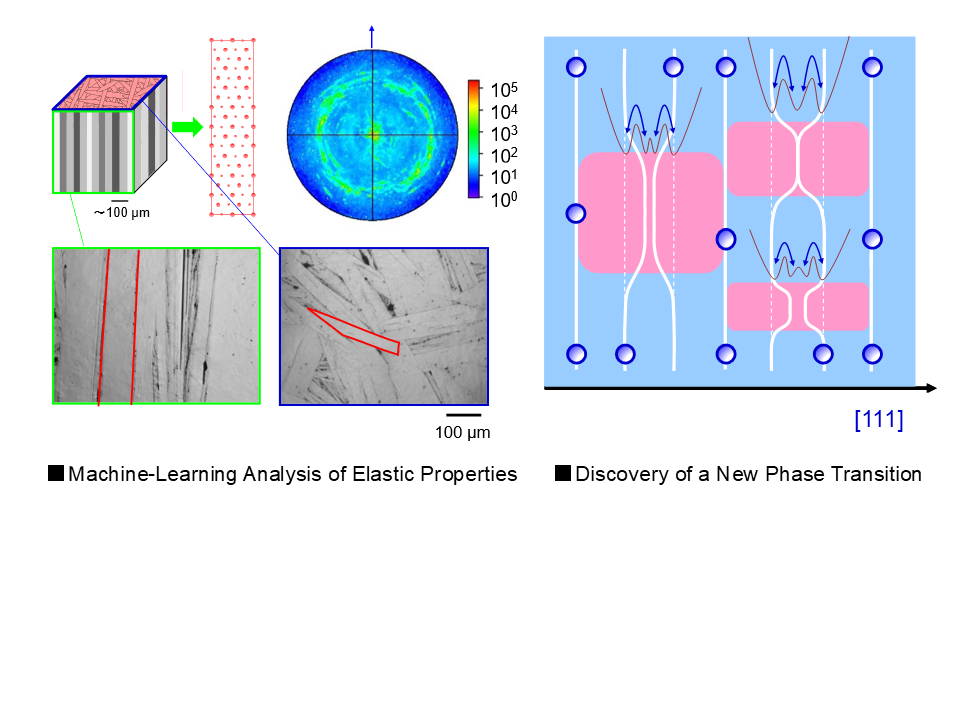

The mechanical properties of materials—such as elasticity and strength—are governed by micro- and nano-scale factors that span multiple length scales, including crystal structure, the directionality of interatomic bonding, crystallographic texture, and the morphology of two-phase microstructures. Identifying which of these factors dominate at each scale, and translating that knowledge into new design principles for achieving superior mechanical performance, is essential for the development of next-generation materials. Our group views materials as hierarchical, complex mechanical systems extending from the nanoscale to the macroscale. By combining elasticity theory, thermodynamics, and machine-learning techniques, we study the mechanics, phase transformations, and microstructural evolution of materials. Through this work we aim to establish novel design rules that will enable the creation of advanced materials for applications in biomedicine and aerospace engineering.

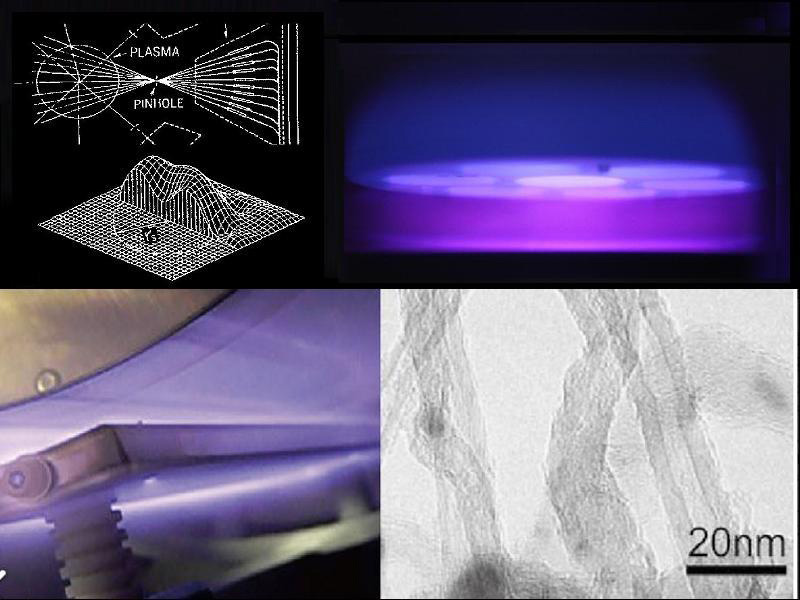

We study plasma in order to control and use it in various applications that will help the world to solve energy/biological/environmental problems. We generate various plasmas in various environments (gas, liquid, or supercritical fluid) and use advanced diagnostic methods to control and understand them. Current studies in applications include thin film deposition, surface modification, nano-structured materials synthesis, treating biological molecules, and environmental treatments.

Top