SCREEN MIRAI Laboratory

SCREEN MIRAI Laboratory is a research hub established in July 2024 by the University of Osaka and SCREEN Holdings on the Suita Campus of the University of Osaka. This laboratory focuses on advancing research and development in various fields, including the miniaturization and complexity of semiconductor manufacturing technologies and life sciences.The laboratory aims to deepen the joint research that has been conducted so far and promote long-term collaboration by combining simulation and experimental methods to develop advanced processes. By linking the university’s research with SCREEN Holdings’ business strategies, the lab seeks to create new technologies and implement them in society.Additionally, the lab is committed to nurturing young researchers with high expertise, thereby strengthening collaboration between industry and academia. Since its establishment on July 1, 2024, the laboratory has made significant progress towards these goals, with concrete results already emerging. This progress is expected to lead to sustainable technological innovation and contributions to society.

Panasonic Science Research Alliance Laboratories

Under the bland slogan of Panasonic Group, “Live Your Best”, our department provides a setting that combines with the potentials of Panasonic and Osaka University, including its research information, technologies, personnel, and facilities, and thereby makes a place for innovation that creates social changing new values. Furthermore, by combining research in a diverse range of fields, including engineering, science, medicine, economics, and psychology, through exchanges and collaboration, our department creates synergistic effects to enable top-level research and personnel development for both parties.

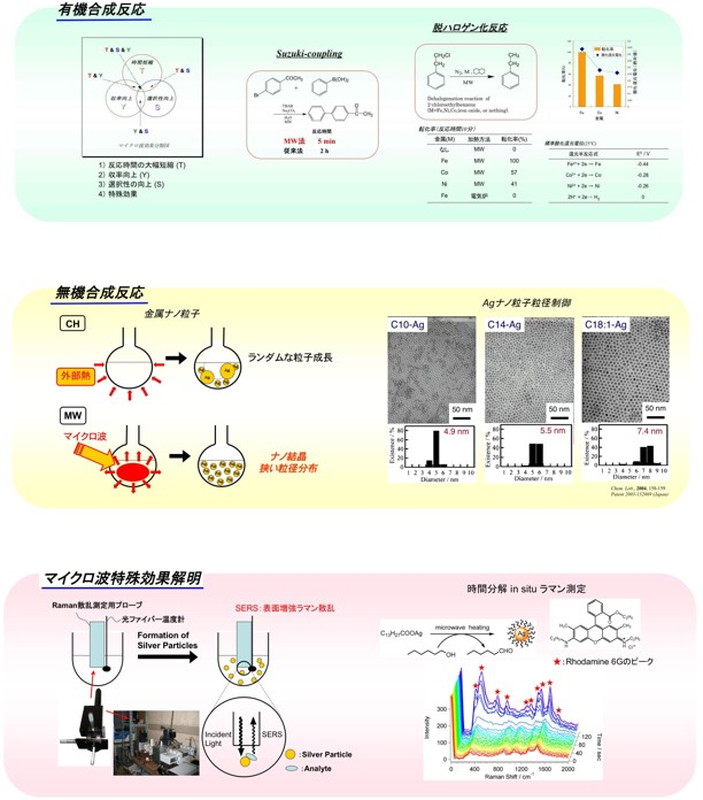

Joint Research Laboratory of Microwave Chemistry

Microwave Driven Chemistry

・Inorganic Reaction

(Nanoparticle, Complex)

・Organic Reaction

(Suzuki-coupling, Esterification)

・Hybrid Catalyst

Kanadevia Square Reserach Alliance Laboratory functions as a strategic hub for comprehensive industry-academia partnerships between Osaka University and Kanadevia. In pursuit of enhancing and evolving Kanadevia’s foundational technologies, the institute undertakes joint research initiatives with affiliated laboratories in the Graduate School of Engineering, the International Center for Biotechnology, and the Joining and Welding Research Institute, with a focus on life sciences and welding technology.

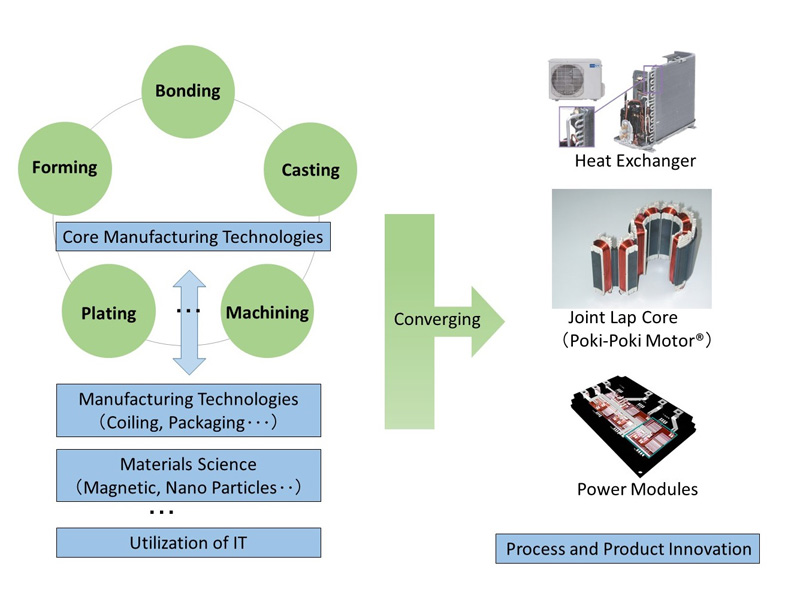

Mitsubishi Electric Research Laboratory of Manufacturing Converging Technologies

We revolutionize production engineering by converge the core manufacturing technologies such as bonding, forming and casting and more to keep international superiority in the manufacturing. We create innovative electric products by using the production engineering.

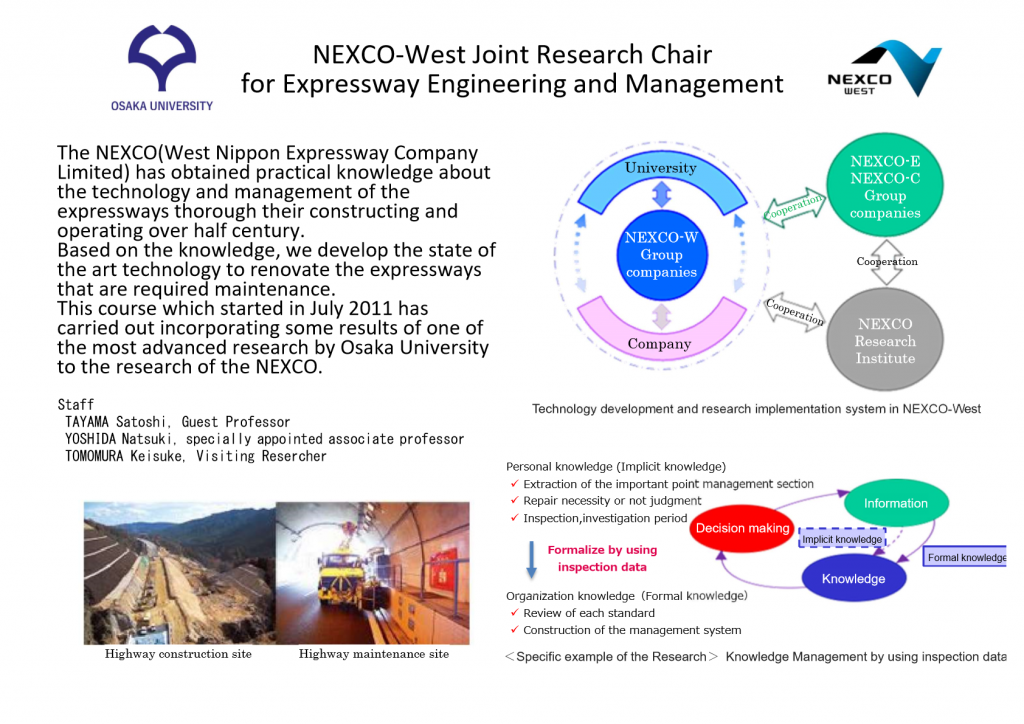

The NEXCO(West Nippon Expressway Company Limited) has obtained practical knowledge about the technology and management of the expressways thorough their constructing and operating over half century.

Based on the knowledge, we develop the state of the art technology to renovate the expressways that are required maintenance.

This course which started in July 2011 has carried out incorporating some results of one of the most advanced research by Osaka University

to the research of the NEXCO.

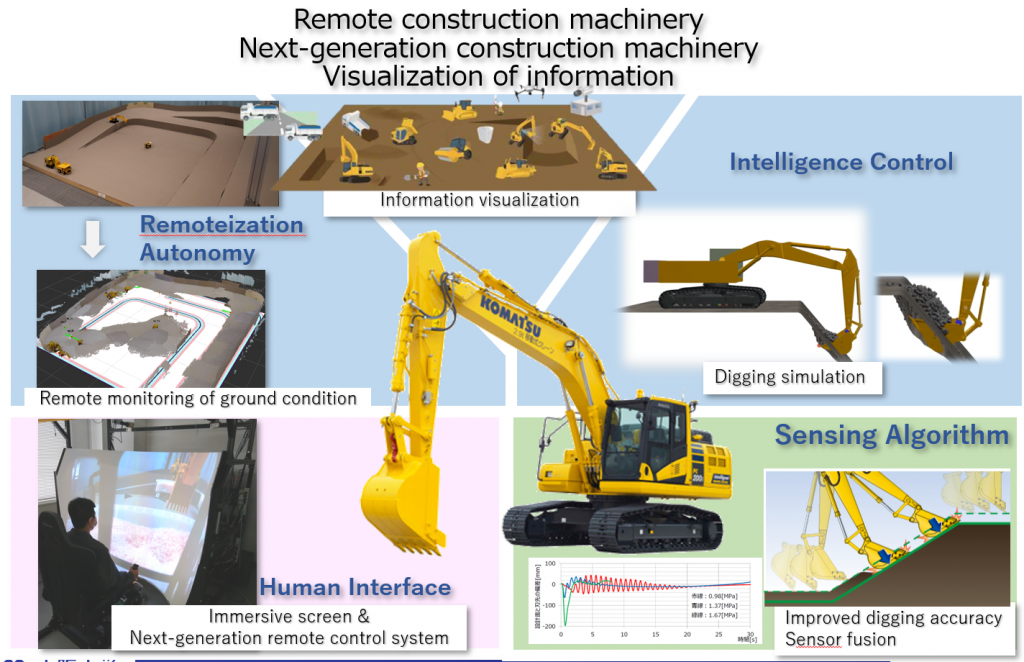

As a base for joint research between Osaka University and Komatsu, we are engaged in improving the productivity of construction & production sites, to realizes automation, remoteness, and efficiency. In addition to utilizing ICT, we will collaborate with various laboratories in a wide range of fields such as control, image processing, sensors, simulation, and other data analysis by utilizing the viewpoints and ideas unique to universities, aiming for speedy establishment.

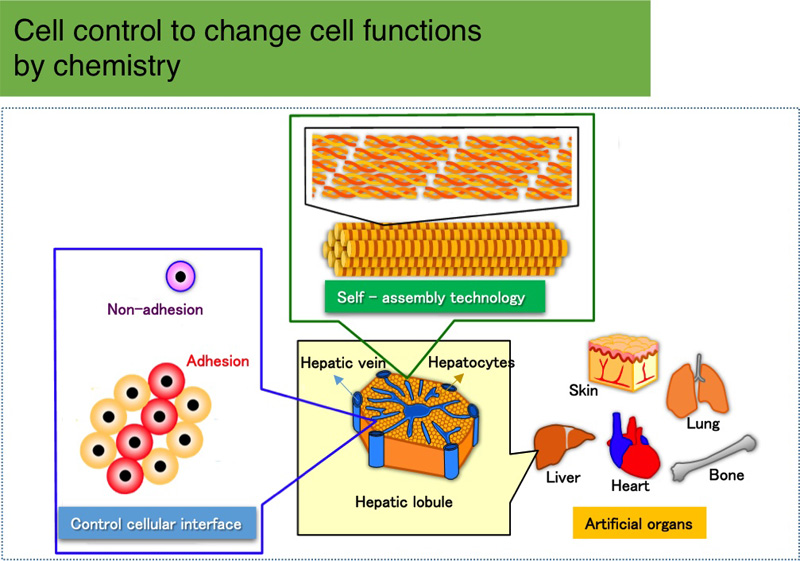

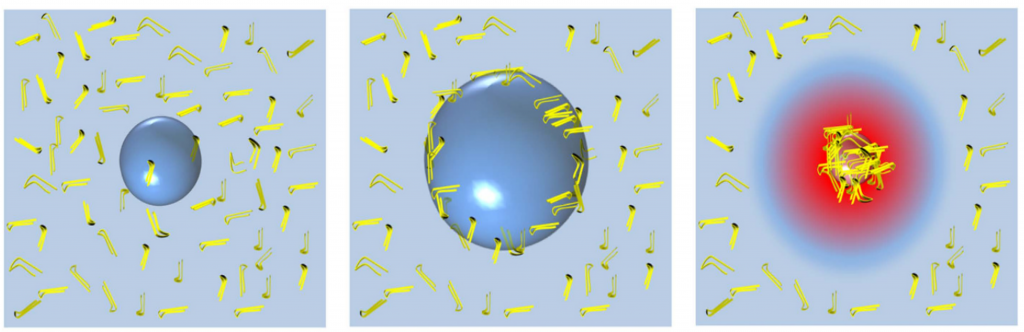

Joint Research Laboratory (TOPPAN) for Advanced Cell Regulatory Chemistry carries out a cooperative research between laboratory of Industrial Organic Chemistry at graduate school of engineering, Osaka University and TOPPAN Holdings Inc.. We are going to develop and commercialize a novel cell regulation technology. In this laboratory, we focus on interaction between cell and synthetic polymer, natural polymer or protein to control cell adhesion, differentiation, proliferation, self-assembly and so on. In addition, we will apply these technologies to 3D tissue construction. 3D tissues are expected to be useful for high throughput drug assays and regenerative medicine.

SiC Applied Technology Joint Research Chair

This Joint Research Chair aims to improve repeatability, safety, stability, and productivity of cell culture for drug discovery screening, cell manufacture in regenerative medicine. To achieve this aim, this Joint Research Chair conducts research on mechanization of manual culture procedures, development of culture containers and instruments applicable for culturing equipment, and construct methodology of objective culture evaluation using cell images. In addition, we are engaged in research and development of culture systems incorporating these technologies.

This joint research chair aims to establish the design of smart factories for advanced medicine such as regenerative medicine.

We acquire and analyze various data of cell culture and develop a manufacturing system of innovative regenerative medicine products that can utilize it in real time.

Furthermore, by linking medical data and product data, we aim to study and construct a system used for continuous quality improvement of products and treatment prediction.

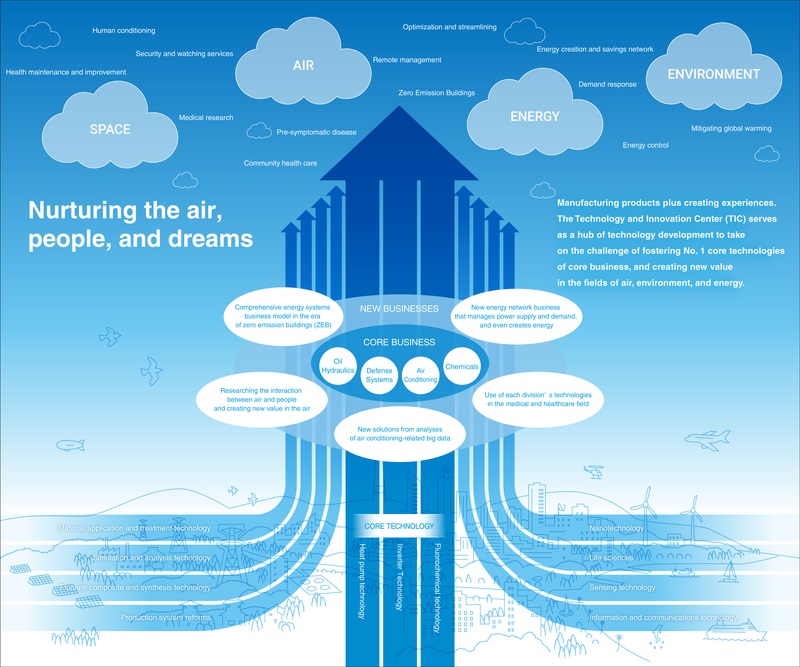

Always DAIKIN between “People” and “Air”

DAIKIN Collaboration Research Institute, which was founded as the former chemical research section of DAIKIN Industries, Ltd. in 2006, was established as a collaborative research project in Osaka University and has obtained many research results until now.

From early 2016, it aims to create fundamental technologies for the innovation of existing products or systems with the collaboration of the air conditioner section and other sections.

In order to continue creating a more comfortable living environment and earth environment, our company DAIKIN Industries now accelerates a challenge to next generation technologies, keeping our eyes wide open into the future from the viewpoint of people living there.

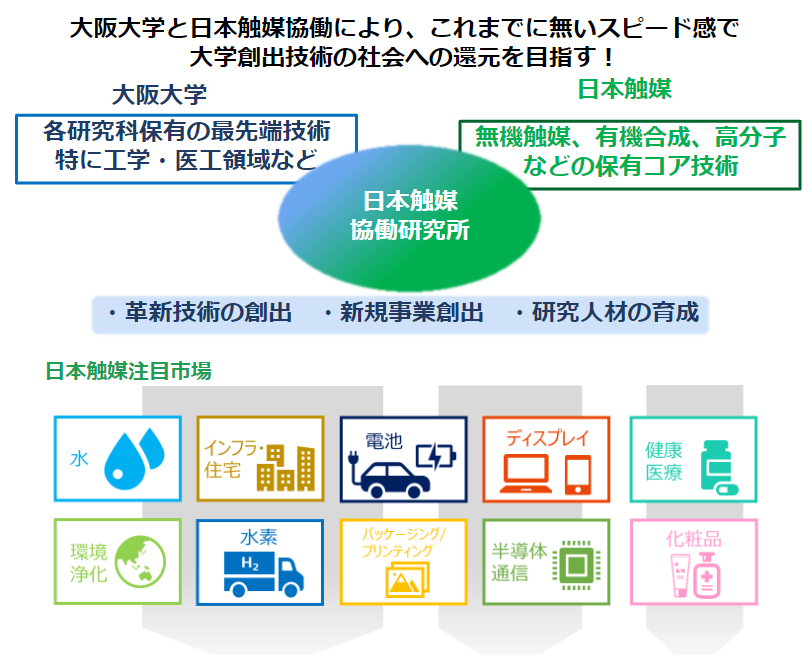

In our research alliance laboratory, fused state-of-the-art of Osaka University technology and accumulated technology of Nippon Shokubai, is working on the creation of new products and technologies that are innovative and competitive.

Our mission is to make a contribution to the stability and growth of the society for the next 100 years.

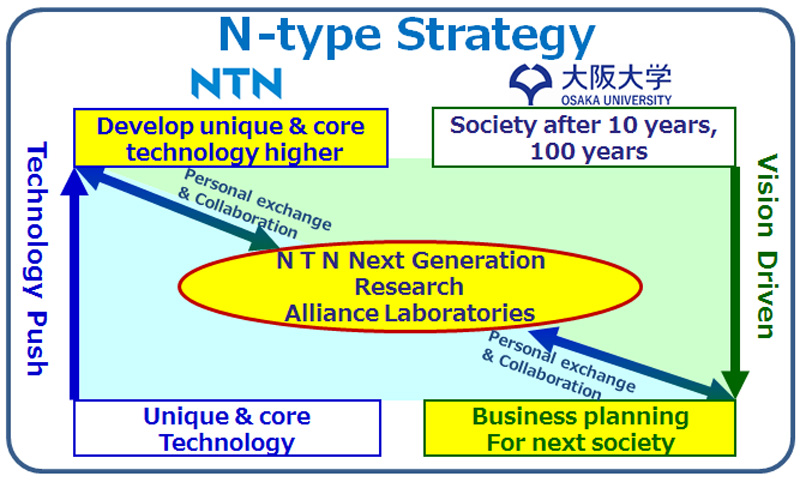

To aim at the transformation to co-creation, Osaka University and NTN are planning and carrying out research with open innovation.

Our institute is based on the “”N-type strategy.””

The strategy is made up a technology push vector and a vision-driven vector.

In ULVAC-OSAKA University Joint Research laboratory for Future Technology, we perform the various studies based on the vacuum technology widely from the preservation of pharmaceutical products to film deposition equipments for the flat-panel display, semiconductor devices and LED devices. Through a framework of joint research with Osaka University, we work for the advanced personnel development, as well as the contribution to development of the science in the medical and engineering fields. We hope to establish networks formed by the interchange of mutual researchers.

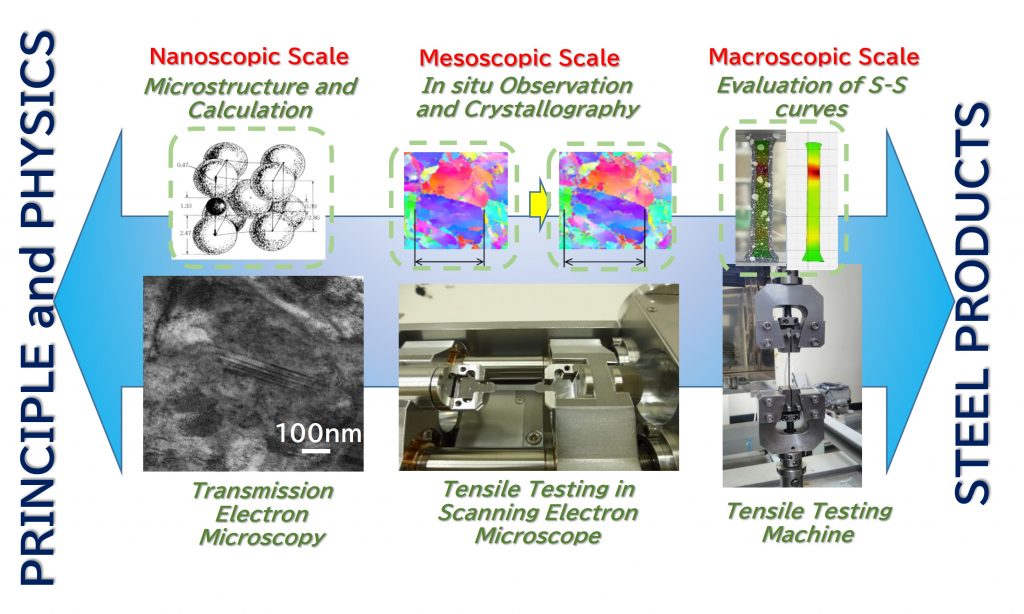

In the evolution of the society and our lifestyles with the progress of science and technology, we will pursue the infinite ability of advanced recyclable steels to guarantee the safety and security in our life, on the representations of lightweight vehicles, high-rise buildings, and energy transportation materials.

We will develop a new multi-physics and multi-scale characterization techniques, resulting in the understanding of a dynamic deformation mechanism in steels, including the time dependent phenomenon. It is a key for us to make a good relationship among several kinds of laboratories in material science divisions.

Metabolomics is the study on investigating comprehensively biological phenomena in vivo by analyzing exhauslive various metabolites generated by life activities. It is useful for elucidating complex systems such as disease prediction, drug discovery support, and food improvement based on scientific evidence. Our laboratories are collaborating with various professors at Osaka University, mainly in the field of metabolomics. Furthermore, since fiscal year 2021, Shimadzu has started the REACH Project, in which Shimadzu employees are dispatched as doctoral students, with the aim of further accelerating collaboration and early social implementation of research results.

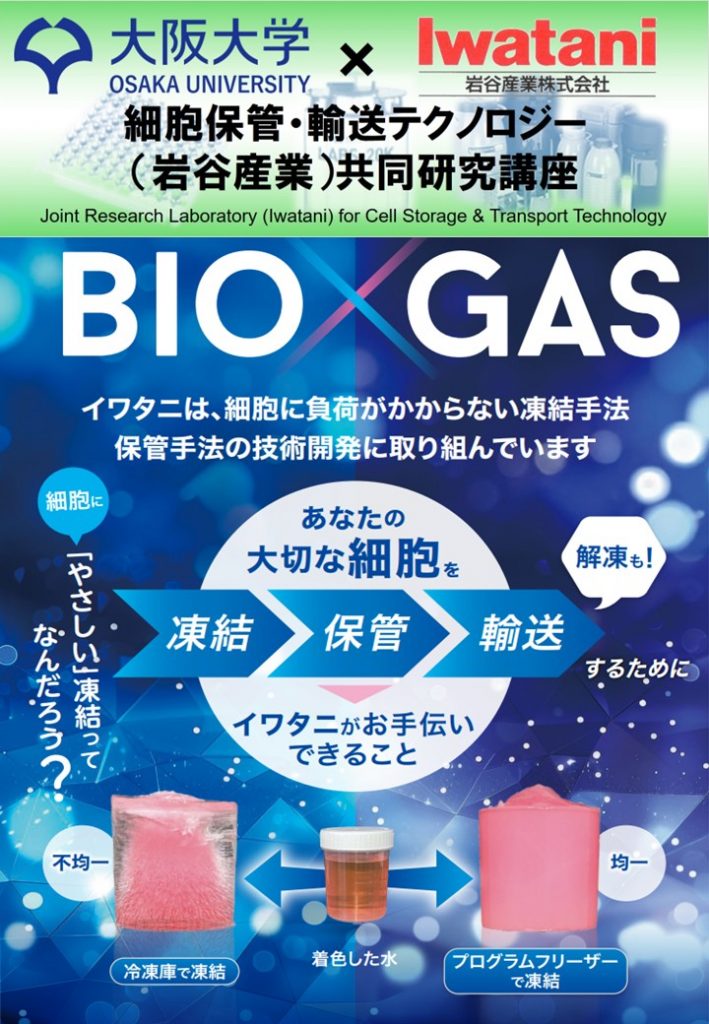

To contribute to the commercialization of new regenerative medicine techniques, we develop technology and equipment for cell storage and transportation by combining Kino-oka lab’s know-how regarding stabilization of cell processing and Iwatani Corporation’s cryogenic engineering experience.

Mobility System Joint Research Chair is aiming at configuring comfortable, eco-friendlly, and sustainable smart city powered by e-Mobility. Research themes are on multi-modal mobility analysis, optimal charging infrastructure design for various electric fleet, and coupling analysis beyond mobility and energy sectors, and so on. Final target of the research chair is to create a prototype of smart city platform in foundation of versatile landscape of the city and community.

In this joint research chair, we are working on research and development of elemental technologies for next-generation CAE, considering the ideal form of next-generation CAE. We will establish innovative structural design and evaluation methods for real structures through digital twin by integrating state-of-the-art fracture prediction and evaluation technology, VMT (Virtual Materials Testing) technology based on crystal plasticity analysis, and machine learning/AI technology.

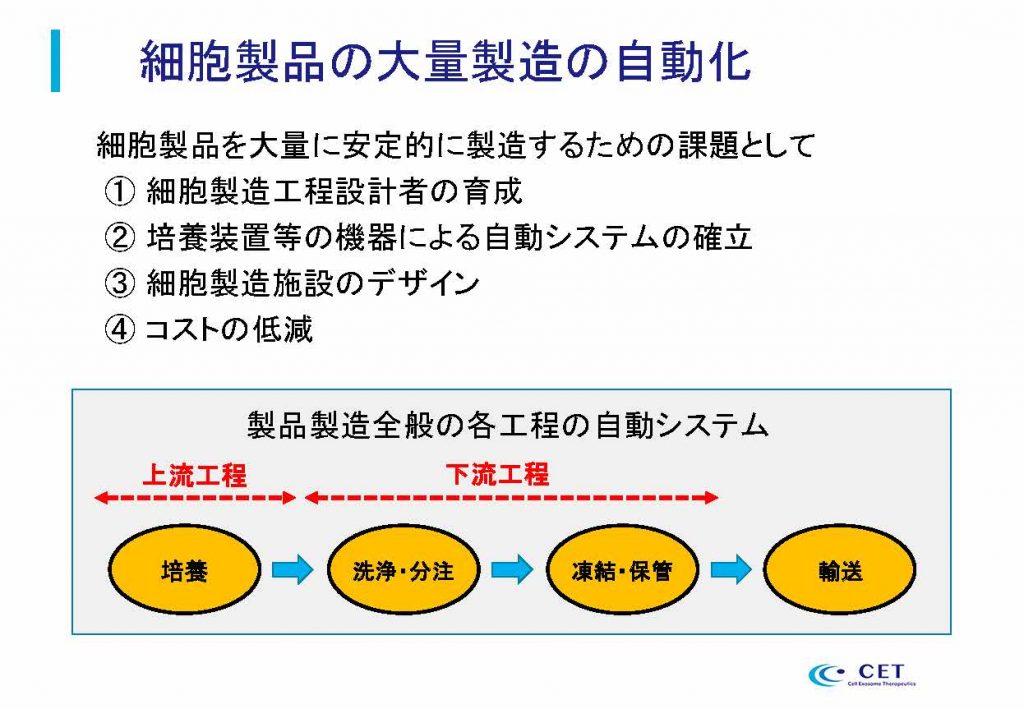

We will work to build an automated system that enables stable and mass production for the practical application of cell therapy using umbilical cord-derived mesenchymal stem cells. In addition, we will connect a series of processes from manufacturing to transportation to medical sites, aiming to realize social implementation of regenerative medicine.

Koji mold is designated as ‘Japanese National Microorganisms’ by The Brewing Society of Japan, and is used in the manufacture of Japanese rice wine, soy sauce, soybean paste, recognized as industrial fungi. This donated laboratory had been established on October 2021. The members in this laboratory proceed research for breeding engineering of koji mold, where we are to investigate the diversity of genomic structure among koji mold and its related fungi and to apply the newly active koji mold. One of the goal of this study may develop fermented foods using new materials which are not used in traditional foods.

Microsonochemistry Joint Research Chair

We are engaged in fundamental research on the control mechanism of chemical reactions in microchannels using ultrasonication and on ultrasonic sensors. We also approach the basic comparative research between ultrasonication and energy from gunpowder action regarding the control of reactions on proteins.

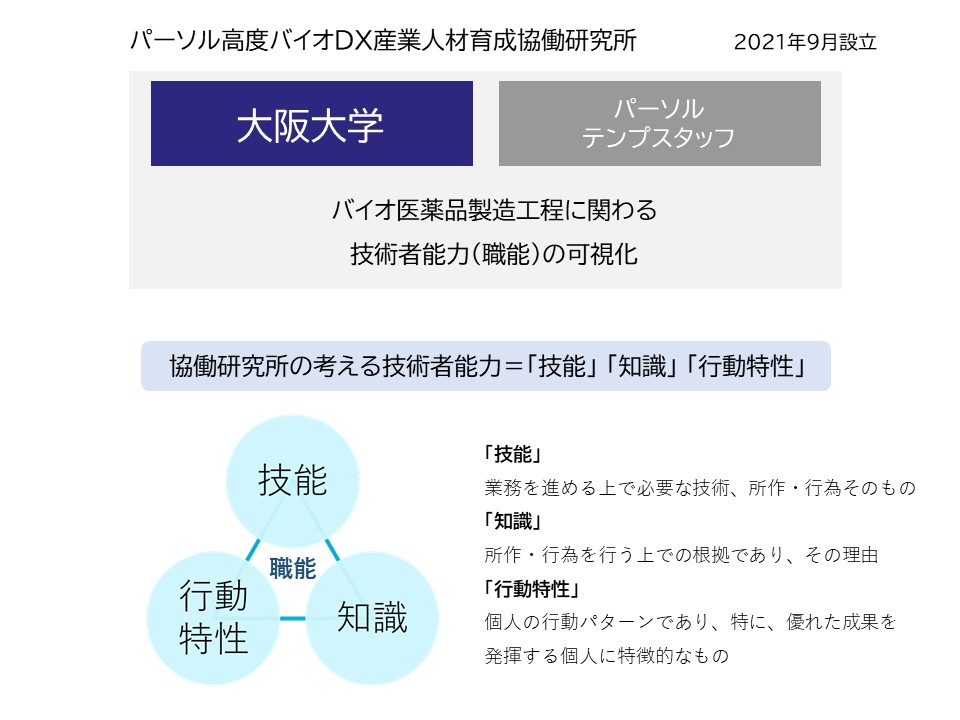

PERSOL Industrial Human Resources Research Alliance Laboratory

This research alliance laboratory was established in September 2021 to evaluate and develop human resources in biotechnology. Osaka University and Persol Tempstaff Corporation will work together to develop an evaluation method based on a job analysis and career visualization, to contribute to high-level human resources in the field of biotechnology.

This is a joint research laboratory among Prof. Matsusaki laboratory of Industrial Organic Chemistry at graduate school of engineering, Osaka University, ITOHAM YONEKYU HOLDINGS INC. and TOPPAN HOLDINGS INC. Prof. Matsusaki has developed a superior method to produce cultured meat using 3D cell printing technology. We work on further development of the techniques to enable its implementation in society (ensuring food safety, cost reduction, mass production, etc.). In addition, as key members of the Consortium for Future Innovation by Cultured Meat, we will contribute to solving environmental and food problems, improving people’s health, and proposing food for the future, in collaboration with people in other research and industrial fields.

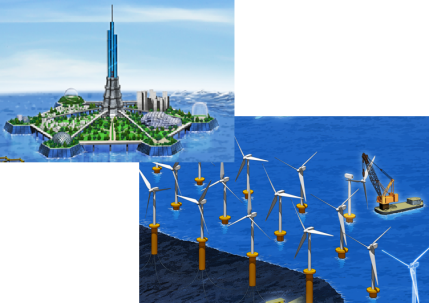

This Joint Research Chair was established in March 2023 as a laboratory that will serve as a driving force to create a new offshore wind industry in Japan and to achieve carbon neutrality by 2050. Then, it is necessary to integrate technologies for offshore wind spreading over various fields. We are working for promoting the industrialization of offshore wind, and for developing human resource who can lead the offshore wind industry.

Top